Abstract

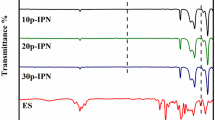

A siliconized epoxy interpenetrating network (IPN) was synthesized from commercially available DGEBA epoxy resin GY250 (Ciba-Geigy, epoxy equivalent = 182–192, viscosity = 9000–12000 cP) and hydroxyl terminated polydimethylsiloxane (PDMS). PDMS and GY250 were thoroughly mixed at 30°C to get the prepolymer. Stoichiometric amounts of PDMS-epoxy prepolymer, γ-aminopropyltriethoxysilane, aliphatic amine curing agent (HY951), and dibutyltindilaurate catalyst, were thoroughly mixed and cast in a mould after evacuating the entrapped air. The cured material was then taken out and post cured at 70°C for 10 h. IPN was characterized by FTIR spectroscopy, SEM, DSC, TGA and viscosity measurements. Incorporation of PDMS in the epoxy matrix increased the viscosity and lowered the exotherm and pot-life. PDMS in IPN increasedT g, heat-distortion temperature and reduced the percentage weight loss with increase in temperature. Incorporation of PDMS drastically reduced the tensile and flexural strengths and hardness. By reducing the tensile and flexural modulus, the siloxane moiety effectively reduced the internal stress of IPN thereby improving its impact strength and percentage elongation. PDMS increased the electric potential gradient of IPN to withstand without breakdown. An increase in the tracking index and arc resistance of IPN were observed, because of the presence of Si-O-Si, which minimized the possibility of forming carbonized path. Volume and surface resistivities of IPN also increased with the incorporation of PDMS. The siliconized epoxy IPN, with better impact and thermal resistance, may be used in automobile and aerospace applications to withstand high temperature, and mechanical stress. The PDMS-epoxy IPN may be used for encapsulation, high temperature and high voltage application due to their low shrinkage and lesser internal stress. With the improved electrical characteristics, IPN may be used for high performance electrical insulation, insulator housings, and encapsulation to withstand high voltage, moisture, oxidation, chemical attack, biological attack, outdoor weathering, contamination, electrical, mechanical and thermal stress.

Similar content being viewed by others

References

Bascom W D, Cottington R L, Jones R L and Peyser P 1975J. Appl. Polym. Sci. 19 2425

Frisch H L 1985Br. Polym. J. 17 149

Gorur R, Johnson L and Hervig H 1991IEEE Trans. Power Delivery 6 1361

Gutman I, Hartings R, Matsuoka R and Konda K 1997IEEE Elect. Insul. Mag. 13 36

Karady G G, Shah M and Brown R L 1995IEEE Trans. Power Delivery 10 1965

Looms J S T 1990Insulators for high voltage (London: Peter Peregrinus Ltd.) pp 17–19

Mackevich J and Shah M 1997IEEE Elect. Insul. Mag. 13 5

Nguyen L T and Suh N P 1984Rubber modified thermoset resins (eds) C K Riew and J K Gillham (Washington DC: Am. Chem. Soc.) Chap. 19

Serier A, Pascault J P and My L T 1991J. Polym. Sci. Polym. Chem. Ed. 29 209

Simmons S, Shah M, Mackevich J and Chang R J 1997IEEE Elect. Insul. Mag. 13 25

Sultan J N and Mc Garry F J 1973J. Appl. Polym. Sci. 13 29

Sung P H and Lin C Y 1997Eur. Polym. J. 33 903

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Thanikai Velan, T.V., Mohammed Bilal, I. Aliphatic amine cured PDMS-epoxy interpenetrating network system for high performance engineering applications—Development and characterization. Bull Mater Sci 23, 425–429 (2000). https://doi.org/10.1007/BF02708394

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF02708394