Abstract

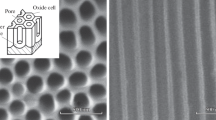

The microporous alumina membrane with asymmetrical structure, having upper layer with pore diameter of 10 nm under and lower layer with pore diameter of 36 nm, was prepared by anodic oxidation using DC power supply of constant current mode in an aqueous H2SO4 solution as a electrolyte. The aluminum plate was pretreated with thermal oxidation, chemical polishing and electrochemical polishing before anodic oxidation. The membranes were prepared by controlling the current density such as a very low current density for upper layer and a high current density for lower layer of membrane. By controlling the cumulative charge density, the thickness of upper layer of membranes was about 6 Μm and the total thickness of membranes was about 80–90 Μm. We found from gas permeation experiments with the membranes prepared by above method that the mechanism of gas permeation of the all membranes prepared under each condition complied with model of the Knudsen diffusion.

Similar content being viewed by others

References

Allen, T., “Particle Measurement”, 4th Ed., Chapman and Hall (1990).

Davis, S. K. and Baltus, R. E., “Transport Studies with Porous Alumina Membranes”,J. Membrane Sci.,71, 247 (1992).

Hoyer, P., Nishio, K. and Masuda, H., “Preparation of Regular Structured Porous Metal Membranes with Two Different Hole Diameters at Two Sides”,Thin Solid Film,286, 88 (1996).

Hwang, S. T. and Kammermeyer, K., “Membranes in Separation”, Krieger Publishing Co. Inc., Malabar, Florida (1984).

Itoh, N., Kato, K., Tsuji, T. and Hongo, M., “Preparation of a Tubular Anodic Alumina Oxide Membrane”,J. Material Sci.,117, 189 (1996).

Kobayashi, Y., Iwasaki, K., Kyodani, T. and Tomita, A., “Preparation of Tubular Alumina Membrane with Uniform Straight Channels by Anodic Oxidation Process”,J. Material Sci.,31, 6185 (1996).

Lee, C. W., Chang, Y. H. and Hahm, Y. M., “Preparation of Porous Alumina Membrane by Anodic Oxidation in Sulfuric Acid”,HWA-HAKKONGHAK,36, 653 (1998a).

Lee, C. W., Kang, H. S., Chang, Y. H. and Hahm, Y. M., “Thermotreatment and Chemical Resistance of Porous Alumina Membrane Prepared by Anodic Oxidation”,Korean J. Chem. Eng.,17, 266 (2000)

Lee, C. W., Lee, Y., Kang, H. S., Chang, Y. H., Hong, Y. H. and Hahm, Y. M., “Effects of Additives on Preparation of Porous Alumina Membrane by Anodic Oxidation in Sulfuric Acid”,J. Korean Ind. & Eng. Chem.,9, 1030 (1998b).

Ma, M. K., Kwon, H. S., Mah, S. K. and Chung, I.J., “Gas Permeation and Separation Characteristics of Alumina Membranes Prepared by Sol-Gel Method”,HWAHAK KONGHAK,29, 557 (1991).

Smith, A. W., “Porous Anodic Aluminum Oxide Membrane”,J. Electrochem. Soc.,120, 1068 (1973).

The Korean Institute of Membrane, “Membrane Separation”, Free Academy, Seoul (1996).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lee, CW., Lee, CI., Shim, W. et al. Characteristics of gas permeation using two-layered alumina membrane prepared by anodic oxidation. Korean J. Chem. Eng. 18, 101–105 (2001). https://doi.org/10.1007/BF02707205

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF02707205