Abstract

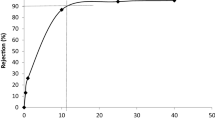

Ultrafiltration of Kraft black liquor was carried out by using an asymmetric membrane in a stirred batch cell, modified to work on a continuous mode. Spiegler-Kedem (SK) model from irreversible thermodynamics was used for the estimation of different membrane-solute parameters, like solute permeability (Pm) and reflection coefficient (Σ). The Pm andΣ so calculated from the above model were used to study the variation of these parameters with other process variables, like bulk concentration, pressure difference and stirrer speed. Finally, a simulation model was developed with the objective to predict permeate flux and rejection, which coupled the film theory, osmotic pressure model and SK model. The simulation results obtained from this study were validated with the experimental data using cellulose acetate membrane of 5,000 Da MWCO. Reasonably good agreements between the predicted and experimental values were observed and the average absolute deviation (AAD) for the prediction of flux and rejection using SK model was found to be 6.3%.

Similar content being viewed by others

Abbreviations

- AAD:

-

average absolute deviation [-]

- Aij :

-

element in the i-th row & j-th column position of the collocation matrix A [-]

- a1, a2, a3 :

-

model parameters of the SK model, defined by Eq. (8) [-]

- Bij :

-

element in the i-th row & j-th column position of the collocation matrix B [-]

- BL:

-

black liquor [-]

- C:

-

local solute concentration [kg·m-3]

- CA :

-

solute concentration [kg·m-3]

- Cb :

-

feed concentration [kg·-3]

- Cm :

-

membrane surface concentration [kg ·-3]

- Cp :

-

permeate concentration [kg·m-3]

- D:

-

diffusivity [m2 · s-1]

- JA :

-

solute flux through membrane [kg·m-2·s-1]

- Jv :

-

volumetric flux [m3·m-2·s-1]

- k:

-

mass transfer coefficient [m·s-1]

- MWCO:

-

molecular weight cut off [-]

- n:

-

speed of the stirrer [rps]

- N:

-

number of internal grid points in orthogonal collocation method[-]

- Pm :

-

local solute permeability per unit membrane thickness [m·s-1] (permeability coefficient)

- Ps :

-

local solute permeability in the membrane [m2·s-1]

- δP:

-

transmembrane pressure difference [Pa]

- Rm :

-

membrane hydraulic resistance [m-1]

- Ro :

-

observed rejection, (1-Cp/Cb), (dimensionless)

- Rr :

-

real rejection, (1-Cm/Cb), (dimensionless)

- r:

-

radius of membrane [m]

- S:

-

cross-sectional area of membrane [m2]

- SK:

-

Spieglar-Kadem [-]

- TMP:

-

transmembrane pressure [-]

- t:

-

time [s]

- UF:

-

ultrafiltration [-]

- V:

-

volume of filtrate collected [m3]

- x:

-

distance coordinate within the membrane with origin lying on the permeate side membrane surface [m]

- δx:

-

membrane thickness [m]

- z:

-

distance away from the membrane surface on feed side [m]

- δ:

-

film thickness [m]

- Μs :

-

solution viscosity [kg·m-1 ·s-1]

- Σ:

-

reflection coefficient, 0 for no rejection, 1 for total rejection

- Ω:

-

stirrer speed [s-1]

- π:

-

osmotic pressure [Pa

- δ:

-

difference [-]

- Μ:

-

viscosity [kg·m-1 · s-1]

- Ν:

-

kinematic viscosity, (Μ/ρ) [m2 · s-1]

- ρ:

-

density [kg·m-3]

- {ie623-01}:

-

function, defined by Eq. (11)

- b:

-

bulk

- i:

-

component

- m:

-

membrane surface

- p:

-

permeate phase

- j:

-

component

References

Bhattacharjee, C., “Analysis of continuous stirred ultrafiltration based on dimensional analysis approach,”Korean J. Chem. Eng.,21, 556 (2004).

Bhattacharjee, C. and Bhattacharya, P. K., “Flux decline analysis in ultrafiltration of Kraft black liquor,”J. Membr. Sci.,82, 1 (1993).

Bhattacharjee, C. and Bhattacharya, P. K., “Prediction of limiting flux in ultrafiltration of Kraft black liquor,”J. Membr. Sci.,72, 137 (1992).

Finlayson, B.A., Nonlinear analysis in chemical engineering, McGraw Hill, New York (1980).

Glimenius, R., “Membrane process for water, pulp and paper,”Desalination,35, 259 (1980).

Iritani, E. and Mukai, Y., “Approach from physicochemical aspects in membrane filtration,”Korean J. Chem. Eng.,14, 347 (1997).

Jung, C.W. and Kang, L. S., “Application of combined coagulation ultrafiltration membrane process for water treatment,”Korean J. Chem. Eng.,20, 855 (2003).

Kim, J. P. and Kim, J. J., “Flux enhancement with glass ball inserted membrane module for the ultrafiltration of dextran solution,”Korean J. Chem. Eng.,20, 99 (2003).

Nguyen, Q. T., Aptel, P. and Neel, J., “Characterization of ultrafiltration membranes, part-II. Mass transport measurements for low and high molecular weight synthetic polymers in water solutions,”J. Membr. Sci.,7, 141 (1980).

Olsen, O., “Membrane technology in the pulp and paper industry,”Desalination,35, 291 (1980).

Press, W. H., Teukolsky, S. A., Vetterling, W. T. and Flannery, B. P.,Numerical recipes in C, Cambridge University Press, UK (1992).

Soltanieh, M. and Gill, W., “Review of reverse osmosis membranes and transport models,”Chem. Eng. Commun.,12, 279 (1981).

Thiruvenkatachari, R., Shim, W.G., Lee, J.W. and Moon, H., “Powdered activated carbon coated hollow fiber membrane: Preliminary studies on its ability to limit membrane fouling and to remove organic materials,”Korean J. Chem. Eng.,22, 250 (2005).

Tsapiuk, E. A., Bryk, M. T., Medvedev, M. I. and Kochkodan, V.M., “Fractionation and concentration of lignosulphonates by ultrafiltration,”J. Membr. Sci.,47, 107 (1989).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sarkar, P., Datta, S., Bhattacharjee, C. et al. Performance study on ultrafiltration of Kraft black liquor and membrane characterization using Spiegler-Kedem model. Korean J. Chem. Eng. 23, 617–624 (2006). https://doi.org/10.1007/BF02706804

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF02706804