Abstract

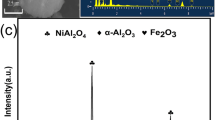

Valuable metals including V, Mo, Ni, Co, and Al were selectively recovered from spent desulfurization catalyst by means of extractive separation. Prior to selective metal recovery the spent catalyst was roasted at temperatures of 400–800 °C, and BET, SEM, and XRD data showed that roasting the spent catalyst at 550 °C gave birth to the surface and pore structures accounting for good extractibility of the roasted spent catalyst. A sequential scheme consisting of leaching and chelate extraction was developed to recover the metals from the spent catalyst roasted at 550 °C and oxygen space velocity of ca. 1800 hr−1.

Similar content being viewed by others

References

Crnojevich, R., Wiewiorowski, E. I., Tinnin, L. R. and Case, A. B.,“Recycling Chromium-Aluminum Wastes from Aluminum Finishing Operations”,J. Metal.,October, 42 (1990).

Fischer, Jr., R. G. and Van Savage, C. A.,“Stripping Metals from Spent Catalysts”, U. S. Patent 4585628 (1986).

Howard, R. A. and Barnes, W. R.,“Process for Recovering Valuable Metals from Spent Catalysts”, U. S. Patent 5013533 (1991).

Inoue, K.,“Solvent Extraction of Nickel and Cobalt at Low pH with Synergistic Mixtures”, Proceedings of 4th Japan-Korea Symposium on Separation Technology, Tokyo, Japan, 311 (1996).

Jeffery, G. H., Bassett, J., Mendham, J. and Denny, R. C, “Vogel’s Textbook of Quantitative Chemical Analysis”, 5th ed., Longman Publishing Co., England, 1989.

Kelebek, S. and Distin, P. A.,“Nickel Extraction from a NickelTungsten Spent Catalyst Using Column Leaching”,J. Chem. Tech. Biotechnol.,44, 309 (1989).

Marafi, M., Stanislaus, A., Mumford, C. J. and Fahim, M.,“Regeneration of Spent Hydroprocessing Catalysts: Metals Removal”,Appl. Catal.,47, 85 (1989).

Nevitt, T. D.,“Process for Removing Metals from Spent Catalyst” , U. S. Patent 4677085 (1987).

Ritcey, G. M. and Ashbrook, A. W.,“Solvent Extraction: Principles and Applications to Process Metallurgy, Part II”, Elsevier Scientific Publishing Co., New York, 1979.

Sebenik, R. F., Lavalle, P. P., Laferty, J. M. and May, W. A., “Recovery of Metal Values from Spent Hydrodesulfurization Catalysts”, U. S. Patent 4495157 (1985).

Smith, B. J. and Wei, J.,“Deactivation in Catalytic Hydrodemetallation 2. Catalyst Characterization”,J. Catal.,132, 21 (1991).

Tamm, P. W., Harnsberger, H. F. and Bridge, A. G.,“Effects of Feed Metals on Catalyst Aging in Hydroprocessing Residuum”,Ind. Eng. Chem. Proc. Des. Dev.,20, 262 (1981).

Thakur, D. S. and Thomas, M. G.,“Catalytic Deactivation in Heavy Petroleum and Synthetic Crude Processing: a Review”,Appl. Catal.,15, 197 (1985).

Tilley, G. L.,“Recovery of Metal Values from Spent Catalysts”, U. S. Patent 4721606 (1988).

Twigg, M. V.,“Catalyst Handbook”, 2nd ed., Wolfe Publishing Co., London, 1989.

Wiewiorowski,“Selective Extraction of Molybdenum and Vanadium from Spent Catalysts by Oxidative Leaching with Sodium Aluminate and Caustic”, U. S. Patent 4666685 (1987).

Wiewiorowski, E., Tinnin, R. and Crnojevich, R.,“A Cyclic Process for Recovery of Metals from Spent Catalysts”, Proceedings of SME Annual Meeting, Phoenix, U. S. A., SME reprint # 88–168, 1988.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Kim, K., Cho, JW. Selective recovery of metals from spent desulfurization catalyst. Korean J. Chem. Eng. 14, 162–167 (1997). https://doi.org/10.1007/BF02706089

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF02706089