Abstract

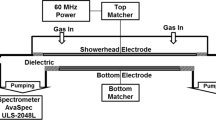

A model-based run-to-run control method has been devised for an inductively coupled plasma etcher and applied to a numerical process for etching SiO2 film with C2F6 plasmas. The controller was designed to minimize a quadratic cost of control error for the oxide etch rate and etch uniformity by run-wise integral action of the RF power, chamber pressure and RF bias voltage. Through numerical simulation, it was shown that the controller can truly minimize the cost even when the set point is given not to be reached by the process.

Similar content being viewed by others

References

Badgwell, T. A., Breedijk, S. G., Bushman, S. G., Butler, S. W., Chatterjee, S., Edgar, T. F., Toprac, A. J. and Trachtenberg, I., “Modeling and control of microelectronics materials processing,”Comp. & Chem. Eng.,19, 1 (1995).

Edgar, T. F., Butler, S. W., Campbell, W. J., Pfeiffer, C., Bode, C., Hwang, S. B., Balakrishnan, K. S. and Hahn, J., “Automatic control in micro-electronics manufacturing: practice, challenges, and possibilities,”Automatica,36, 1567 (2000).

Hankinson, M., Vincent, T. and Irani, K. B., “Integrated real-time and R2R control of etch depth in reactive ion etching,”IEEE Trans. Semi-conduct. Manufact.,10, 121 (1997).

Kim, B. W., Kim, S. M. and Kim, K. H., “Modeling of plasma etching using a generalized regression neural network,”Vacuum,71, 497 (2003).

Kim, W. C., Chin, I. S., Lee, K. S. and Choi, J. H., “Analysis and reduced-order design of quadratic criterion-based iterative learning control using singular value decomposition,”Comp. & Chem. Eng.,24, 1815 (2000).

Lee, J. H., Lee, K. S. and Kim, W. C., “Model-based interactive learning control with a quadratic criterion for time-varying linear systems,”Automatica,36, 641 (2000).

Raul, S. and Kushner, M. J., “Controller design issues in the feedback control of radio frequency plasma processing reactors,”J. Vac. Sci. Technol. A.,17, 704 (1999).

Sarfaty, M., Baum, C., Harper, M., Hershkowitz, N. and Shohet, J. L.,Process control, diagnostics, and modeling in semiconductor manufacturing, edited by Meyyappan, M., Economou, D. and Butler, S. W., Electrochemical Society, New York (1997).

Seo, S. T., Lee, Y. H., Lee, K. S., Yang, D. R. and Choi, B. K., “Run-to-run control of inductively coupled C2F6 plasmas etching of SiO2: construction of a numerical process with a CFD code,”Korean J. Chem. Eng.,22, 822 (2005).

Wang, J., Peter He, Q., Joe Qin, S., Bode, C. A. and Purdy, M. A., “Recursive least squares estimation for R2R control with metrology delay and its application to STI etch process,”IEEE Trans. Semiconduct. Manufact.,18, 309 (2005).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Seo, S.T., Lee, K.S. & Yang, D.R. Run-to-run control of inductively coupled C2F6 plasma etching of SiO2: Multivariable controller design and numerical application. Korean J. Chem. Eng. 23, 199–202 (2006). https://doi.org/10.1007/BF02705716

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF02705716