Abstract

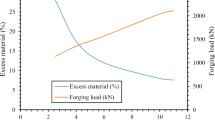

The paper reports on an investigation into the various aspects of closed die cold forging of hexagonal powder preforms, which have been compacted and sintered from atomized powder. It is found that for certain dimensional ratios of the preform, the die pressure is minimum. An attempt has been made determine the die pressures developed during the closed die forging of the hexagonal powder preform by using an upper bound approach. The results so obtained are discussed critically to illustrate the interaction of various process parameters involved and are presented graphically

Similar content being viewed by others

References

Deryagin B V 1952 What is friction?Izď, Akad, Nauk. USSR

Jha A K, Kumar S 1983 Forging of metal powder preforms.Int. J. Mach. Tool Des. Res. 23: 201–206

Jha A K, Kumar S 1984 Forging of a hollow metal powder preform disc.Adv. Technol. Plast. Jpn. 1: 353–358

Jha A K, Kumar S 1985 Analysis of axisymmetric cold processing of metal powder preforms.J. Inst. Eng. India 65: 169–174

Ramakrishnan P 1980 Forging of metal powder preforms.Proc. Int. Seminar on Metal Working Technology Today and Tomorrow, NIFFT, Ranchi, pp 43–46

Sagar R, Juneja B L 1980 An upper bound solution for closed die forging of hexagonal shapes.Int. J. Mach. Tool Des. Res. 20: 67–73

Tabata T, Masaki S 1975 Plane strain extrusion of porous materials.J. Jpn. Soc. Technol. Plast. 16: 279–284

Tabata T, Masaki S, Hosokawa K 1980 A compression test to determine the coefficient of friction in forging P/M preforms.Int. J. Powder Metall. Powder Technol. 16: 149–155

Tabata T, Masaki S, Abe Y 1977 A yield criterion for porous metals and analysis of axial compression of porous discs.J. Jpn. Soc. Technol. Plast. 18: 373–380

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Ranjan, R.K., Kumar, S. An upper bound solution for closed die sinter forging of hexagonal shapes. Sadhana 29, 263–273 (2004). https://doi.org/10.1007/BF02703776

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF02703776