Abstract

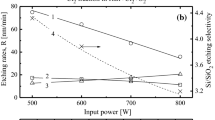

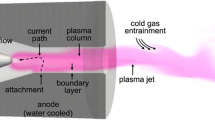

Based on the concept of independent control of ion flux and ion-bombardment energy, a global selfconsistent model was proposed for etching in a high-density plasma reactor. This model takes account of the effect on the plasma behavior of separate rf chuck power in an Inductively Coupled Plasma etching system. Model predictions showed that the chuck power controls the ion bombardment energy but also slightly increases the ion density entering the sheath layer, resulting in an increase in etch rate (or etch yield) with increasing this rf chuck power. The contribution of the capacitive discharge to total ion flux in the ICP etching process is less than about 6% at rf chuck powers lower than 250 W. As a model system, etching of InN was investigated. The etch yield increased monotonically with increasing the rf chuck power, and was substantially affected by the ICP source power and pressure. The ion flux increased monotonically with increasing the source power, while the dc-bias voltage showed the reverse trend.

Similar content being viewed by others

References

Cho, H., Hahn, Y. B., Hays, D. C., Abernathy, C. R., Donovan, S.M. and Mackenzie, J. D., “III-Nitride Dry Etching: Comparison of Inductively Coupled Plasma Chemistries,” and Pearton, S. J.,J. Vac. Sci. Technol. A,17(4), 2202 (1999).

Cho, H., Vartuli, C. B., Donovan, S. M., Abernathy, C. R., Pearton, S. J., Shul, R. J. and Constantine, C., “Cl2-Based Dry Etching of the AlGaInN System in Inductively Coupled Plasmas,”J. Vac. Sci. Technol. A,16, 1631 (1998).

Collision, W. and Kushner, M. J., “Conceptual Design of Advanced Inductively Coupled Plasma Etching Tools Using Computer Modeling,”Appl. Phys. Lett.,68, 903 (1996).

Economou, D. J., Bartel, T. J., Wise, R. S. and Lymberopoulos, D. P., “Two-Dimensional Direct Simulation Monte Carlo (DSMC) of Reactive Neutral and Ion Flow in a High Density Plasma Reactor,”IEEE Trans. Plasma Sci.,23, 581 (1995).

Hahn, Y. B., Hays, D. C., Cho, H., Jung, K. B., Abernathy, C. R. and Pearton, S. J., “Effect of Inert Gas Additive Species on Cl2 High Density Plasma Etching of Compound Semiconductors: Part I. GaAs and GaSb,”Appl. Surf. Sci.,147, 207 (1999).

Hahn, Y. B., Hays, D. C., Cho, H., Jung, K. B., Abernathy, C. R. and Pearton, S. J., “Effect of Inert Gas Additive Species on Cl2 High Density Plasma Etching of Compound Semiconductors: Part II. InP, InSb, InGaP and InGaAs,”Appl. Surf. Sci.,147, 215 (1999).

Hahn, Y. B., Hays, D. C., Donovan, S. M., Abernathy, C. R., Han, J., Shul, R. J., Cho, H., Jung, K. B. and Pearton, S. J., “Reactive Ion Beam Etching of GaAs and Related Compounds in an Inductively Coupled Plasma of Cl2-Ar Mixture,”J. Vac. Sci. Technol. A,17(3), 763(1999).

Hahn, Y. B., Lee., J.W., Vawter, G. A., Shul, R. J., Abernathy, C. R., Hays, D. C., Lambers, E. S. and Pearton, S. J., “Effect of Additive Noble Gases in Chlorine-Based Inductively Coupled Plasma Etching of GaN, InN and AlN,”J. Vac. Sci. Technol. B,17(2), 366 (1999).

Kortshagen, U., Pukropski, I. and Tsendin, L. D., “Experimental Investigation and Fast Two-Dimensional Self-Consistent Kinetic Modeling of a Low-Pressure Inductively Coupled rf Discharge,”Physical Review E,51, 6063 (1995).

Lieberman, M. A. and Gottscho, R. A., in “Physics of Thin Films,” ed. by Francombe, M. and Vossen, J., Academic Press, N. Y. (1993).

Lieberman, M. A. and Lichtenberg, A. J., “Principles of Plasma Discharges and Materials Processing,” John-Wiley and Sons, Inc., N. Y. (1994).

Pearton, S. J., Abernathy, C. R. and Ren, F., “Low Bias Plasma Etching of GaN, AlN and InN,”Appl. Phys. Lett.,64, 2294 (1994).

Rauf, S. and Kushner, M. J., “Model for Noncollisional Heating in Inductively Coupled Plasma Processing Sources,”J. Appl. Phys.,81, 5966 (1997).

Shul, R. J., in “GaN and Related Materials,” ed. S. J. Pearton, Gordon and Breach, N. Y. (1997).

Shul, R. J., Briggs, R. D., Pearton, S. J., Vartuli, C. B., Abernathy, C. R., Lee, J.W., Constantine, C. and Barratt, C., “Etching of Ga-Based III-V Semiconductors in Inductively Coupled Ar and CH4/ H2-Based Plasma Chemistries,”Mat. Res. Soc. Symp. Proc.,449, 969 (1997).

Shul, R. J., McClellan, G. B., Casalnuovo, S.A., Rieger, D. J., Pearton, S. J., Constantine, C., Barrat, C., Karlicek, R. F. Jr., Tran, C. and Schurman, M., “Inductively Coupled Plasma Etching of GaN,”Appl. Phys. Lett.,69, 1119 (1996).

Stewart, R. J., Vitello, P. and Graves, D. B., “Two Dimensional Fluid Model of High Density Inductively Coupled Plasma Sources,”J. Vac. Sci. Technol. B,12, 478 (1994).

Wu, H.-M., Yu, B.W., Krishnan, A., Li, M., Yang, Y., Yan, J.-P. and Yuan, D.-P., “Two-Dimension Fluid Model Simulation of Bell Jar Top Inductively Coupled Plasma,”IEEE Trans. Plasma Sci.,25, 776 (1997).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hahn, YB., Pearton, S.J. A unified global self-consistent model of a capacitively and inductively coupled plasma etching system. Korean J. Chem. Eng. 17, 304–309 (2000). https://doi.org/10.1007/BF02699045

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF02699045