Abstract

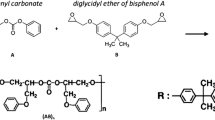

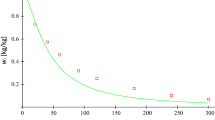

A twophase mass transfer model has been developed to predict the polymer molecular weight for the semibatch melt polymerization process of polycarbonate, in which the reaction melt viscosity is high and the mass transfer of volatile by-product is the rate-controlling step. The model simulation results have been compared with the experimental data reported in the published literature regarding the number average molecular weight and the reaction product composition. The mass transfer coefficient for phenol [(kla)p] in the melt polymerization process of polycarbonate has been estimated.

Similar content being viewed by others

References

Chaudhari, R. V., Gholap, R. V., Emig, G. and Hofmann, H., “Gas-Liquid Mass Transfer in Dead-End Autoclave Reactors”,Can. J. Chem. Eng.,65, 744 (1987).

Kawase, Y. and Moo-Young, M., “Volumetric Mass Transfer Coefficients in Aerated Stirred Tank Reactors with Newtonian and Non-Newtonian Media”,Chem. Eng. Res. Des.,66(5), 284 (1988).

Kim, Y., Choi, K.Y. and Chamberlin, T.A., “Kinetics of Melt Transesterification of Diphenyl Carbonate and Bisphenol-A to Polycarbonate with LiOH H2O Catalyst”,Ind. & Eng. Chem. Res.,31(9), 118 (1992).

Kim, Y.and Choi, K. Y., “Multistage Melt Polymerization of Bisphenol-A and Diphenyl Carbonate to Polycarbonate”,J. Appl. Polym. Sci.,49, 747 (1993).

Laubriet, C, LeCorre, B. and Choi, K. Y., “Two-Phase Model for Continuous Final Stage Melt Polycondensation of Poly (ethylene terephthalate). 1. Steady-State Analysis”,Ind. & Eng. Chem. Res.,30(1), 2 (1991).

Ledakowicz, S., Nettelhoff, H. and Deckwer, W. D., “Gas-Liquid Mass Transfer Data in a Stirred Autoclave Reactor”,Ind. & Eng. Chem. Fundam.,23(4), 510 (1984).

Prausnitz, J. M., “Molecular Thermodynamics of Fluid-Phase Equilibria”, Prentice Hall, Englewood Cliffs, N. J. (1969).

Rafler, G., Reinisch, G., Bonatz, E. and Versaumer, H., “Kinetics of Mass Transfer in the Melt Polycondensation of Poly(ethylene terephthalate)”,J. Macromol. Sci. Chem.,A 22(10), 413 (1985).

Ramachandran, P. A. and Chaudhari, R. V., “Three-Phase Catalytic Reactors”, Gordon & Breach Sci. Publish., N. Y. (1983).

Ravindranath, K. and Mashelkar, R.A., “Modeling of Poly (ethylene terephthalate) Reactors: 5. A Continuous Prepolymerization Process”,Polym. Eng. & Sci.,22(10), 619 (1982).

Rosenbrock, H. H., “An Automatic Method for Finding the Greatest or Least Value of a Function”,Computer J.,3, 175 (1960).

Sherwood, T. K., Pigford, R. L. and Wilke, C. R., “Mass Transfer”, McGraw Hill, N. Y. (1975).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kim, Y. Two phase mass transfer model for the semibatch melt polymerization process of polycarbonate. Korean J. Chem. Eng. 15, 671–677 (1998). https://doi.org/10.1007/BF02698997

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF02698997