Abstract

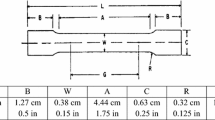

This study is concerned with the fabrication in heavy section of the titanium alloys Ti-8Mo-8V-2Fe-3Al (Ti-8823) and Ti-6Al-6V-2Sn (Ti-662). The technique utilized to achieve 84 pct reduction during the extrusion of heavy section cylindrical hollows is given. The response to subsequent aging of both alloys is described in terms of the effect on important mechanical properties such as yield and ultimate tensile strength, ductility and fracture toughness. For the Ti-8823 alloy extruded in heavy section, it is shown that the optimum heat treatment consists of aging directly after hot working rather than the more common solution treatment and age cycle. With the former heat treatment, uniform through the thickness mechanical properties are obtained. Uniform mechanical properties are also obtained through the section of the Ti-662 extrusion with a solutionizing and overaging heat treatment.

Similar content being viewed by others

References

Aerospace Structural Metals Handbook, Code 3721, vol. 4, December, 1970.

W. H. Heil: “New Developments in High Strength Titanium Alloys,” presented at Titanium Course, New York University, New York, N.Y., September, 1969.

E. Bohanek:Evaluation of Several Commercial Heat of Ti-8Mo-8V-2Fe-3Al, Tech. Report No. 45, Titanium Metals Corporation of America, Toronto, Ohio, August, 1970.

H. A. Russell: Private communication, Titanium Metals Corporation of America, Pittsburgh, Pa., July, 1969.

J. R. Douglas and T. Altan: AMMRC CTR 72-25, Army Materials and Mechanics Research Center, Watertown, Maine, November, 1972.

D. Avery:Metal Progr., February, 1977, vol. 111, p. 52.

R. Chait and T. S. DeSisto: AMMRC PTR 72-5, Army Materials and Mechanics Research Center, Watertown, Maine, October, 1972.

Standard E399-72, Annual Book of ASTM Standards, Part 31, American Society for Testing and Materials, Philadelphia, Pa., 1973.

A. M. Adair and J. A. Roberson:Proc. 2nd International Conference on Strength of Metals and Alloys, ASM, Metals Park, Ohio, 1970, p. 932.

R. Chait:Met. Trans. A., 1975, vol. 6A, p. 2301.

P. J. Fopiano and C. F. Hickey, Jr.:J. Test and Evaluation, 1973, vol. l,p. 514.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Chait, R., Stead, C. Fabrication and properties of heavy section extrusions of Ti-6Al-6V-2Sn and Ti-8Mo-8V-2Fe-3AI alloys. Metall Trans B 8, 371–376 (1977). https://doi.org/10.1007/BF02696923

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02696923