Abstract

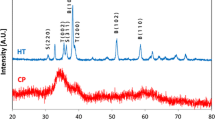

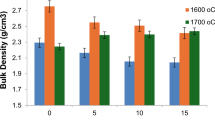

Results of a study of the phase composition and structure of corundum-graphite materials on a combined pitch-ethylsilicate binder with an additive of B2O3 are considered. The mechanism of formation of \-SiC in mixtures based on corundum, silicon carbide, graphite, and a silicon additive with the use of the combined binder is described. The ecological problems of the use of pitch and ethyl silicate in the composition of the binder are solved by involving the products of the gel destruction and pitch coking in the reactions of low-temperature synthesis of oxygen-free compounds, β-SiC in the first place.

Similar content being viewed by others

References

A. V. Dunikov, “Thermodynamic study of the Si - O2 - C system and low-temperature synthesis of silicon carbide binder in graphite-oxide materials,” in:Abs. Rep. Conf. “Structures and Technology of Parts from Nonmetallic Materials, ” Part 1 (in Russian), Nauka, Moscow (1984), p. 32.

G. D. Semchenko and A. V. Dunikov, “Some special features of fabrication of corundum-graphite refractories on silicon carbide binder,” in:Abs. Rep. IV All-Union Conf. on Solid-State Chemistry (in Russian), Nauka, Sverdlovsk (1985), pp. 62–63.

G. D. Semchenko, S. M. Logvinkov, S. V. Tishchenko, et al., “Synthesis and investigation of silicon carbide in corundum and corundum-graphite mixtures on ethylsilicate binder,” in:Abs. Rep. All-Union Conf. on the Crystal Chemistry of Intermetallic Compounds (in Russian), LGU, Lvov (1989), p. 117.

G. D. Semchenko, L. G. Kalinchuk, G. A. Gogotsi, et al., “Properties of corundum-graphite and periclase-carbon refractories on pitch-ethylsilicate binders,” in:Abs. Rep. Sci.-Tech. Conf. “Research and Use of Binders for the Production of Refractories” (in Russian), VostIO, Sverdlovsk (1990), p. 75.

G. D. Semchenko, A. V. Dunikov, L. G. Stochek, et al., USSR Inv. Certif. No. 1028640, “Mixture and method for manufacturing refractories,”Otkr. Izobr., No. 26 (1983).

G. D. Semchenko, A. V. Dunikov, L. G. Stochek, et al., USSR Inv. Certif. No. 1128532, “A mixture for manufacturing refractories,”Otkr. Izobr. (1984).

G. D. Semchenko, A. V. Dunikov, L. G. Stochek, et al., USSR Inv. Certif. No. 1095566, “A mixture for manufacturing refractories,”Otkr. Izobr. (1984).

G. D. Semchenko and A. V. Dunikov, USSR Inv. Certif. No. 1179637, “A binder and a method for its fabrication,”Otkr. Izobr. (1985).

G. D. Semchenko, “Possibility of improving the quality of graphite-bearing refractories,” in:Coll. of Works UGNIIO “Saving of Resources in the Production and Use of Refractories and Utilization of Waste” (in Russian), OP KhOUS, Kharkov (1992), pp. 37–38.

G. D. Semchenko, A. V. Dunikov, Ya. G. Belik et al, “Technology of corundum-graphite refractories on a combined binder,”Ogneupory, No. 11, 30 – 33 (1984).

G. D. Semchenko and A. V. Dunikov, “Advancing the quality of corundum-graphite refractories,” in:Abs. Rep. All-Union Sci.-Tech. Conf. “Improvement of the Quality and Structure of Production in the Refractory Industry” (in Russian), Nauka, Zaporozhe (1986), p. 43.

G. D. Semchenko and A. V. Dunikov, “Elevating the strength of corundum-graphite refractories by purposeful improvement of the binder,” in:Abs. Dokl. All-Union Sci.-Tech. Conf. “Improving the Quality and the Structure of Production of Refractories” (in Russian), Nauka, Moscow (1986), p. 43.

Yu. G. Gogotsi, V. Zh. Shemet, V. A. Lavrenko, and A. V. Dunikov, “Resistance of corundum-graphite refractories to oxidation,” in:Abs. Rep. Sci.-Tech. Conf. “Development and Use of High-Resistance Refractories in Steel-Casting Production ” (in Russian), Chermetinformatsiya, Moscow (1985), p. 14–15.

G. D. Semchenko, A. V. Dunikov, and Yu. G. Gogotsi, “Corundum-graphite materials on a silicon carbide binder,” in:Abs. Rep. “Structure and Technology of Parts from Nonmetallic Materials, ”Part 1 (in Russian), Nauka, Moscow (1984), p. 30.

A. V. Dunikov, G. D. Semchenko, and G. A. Gogotsi, “Corundum-graphite materials for casting steel,”Ogneupory, No. 2, 14–17(1984).

G. D. Semchenko, A. S. Berezhnoi, and A. V. Dunikov, “Effect of the phase composition on the properties of a corundum-graphite material,” in:Abs. Rep. Int. Conf. “Development of Technical Chemistry in Ukraine, ” Issue 2 (in Russian), KPI, Kiev (1985), pp. 12–13.

G. D. Semchenko, A. S. Berezhnoi, E. E. Starolat, et al., “Synthesis of oxygen-free compounds from sol-gel compositions,” in:Abs. Rep. XIII Ukrainian Conf. on Inorganic Chemistry, Part 2 (in Russian), KGU, Uzhgorod Kiev (1992), p. 245.

G. D. Semchenko, A. V. Dunikov, V. V. Kalin, and T. V. Kovalenko, “High-resistance corundum-graphite material on a combined binder,” in:Abs. Rep. Int. Conf. “Development of Technical Chemistry in Ukraine, ” Issue 2 (in Russian), KPI, Kiev (1995), pp. 16–17.

G. D. Semchenko, S. V. Tishchenko, I. N. Opryshko, et al., “Thermal destruction of gel compositions based on ethyl silicate and boric acid,”Steklo Keram., No. 1, 23 – 26 (1999).

G. D. Semchenko, “Physicochemical processes that occur upon heating of pitch and its mixtures with ethyl silicate,”Ogneup. Tekh. Keram., No. 4, 14–19 (1997).

G. D. Semchenko, E. E. Starolat, A. V. Dunikov, and S. M. Logvinkov, USSR Inv. Certif. No. 1830380, “A method for fabricating silicon carbide,”Izobreteniya, No. 2, 118 (1993).

G. D. Semchenko, “Physicochemical aspects of protection of graphite from oxidation upon heat treatment of mixtures on ethylsilicate binder,”Ogneup. Tekh. Keram., No. 11, 20 – 23 (1998).

G. D. Semchenko, “Low-temperature synthesis of SiC in heat treatment of gels from hydrolyzed ethyl silicate,”Ogneup. Tekh. Keram., No. 9, 14 – 19 (1996).

G. D. Semchenko, “Part I. Fabrication of binders for ceramic production by the sol-gel method. 4. Structure and processes of gel transformation in heat treatment; creation of carbon clathrate in gel clusters,”Ogneup. Tekh. Keram., No. 7, 6 – 14 (1999).

I. N. Shuteeva, Yu. G. Gogotsi, G. D. Semchenko, and L. G. Kalinchuk, “A thermographie study of protective properties of ethylsilicate binders in graphite oxidation,” in:Abs. Rep. Conf. “Use of Thermal Analysis for Intensification of Technological Processes and Creation of Advanced Materials ” (in Russian), Nauka, Minsk (1988), p. 50.

A. V. Dunikov, G. D. Semchenko, V. V. Makarenko, and L. P. Gurenko, “Choice of regimes of heat treatment of refractory mixtures on combined pitch-bearing binders,” in:Abs. Rep. “Use of Thermal Analysis in Intensification of Technological Processes and Creation of Advanced Materials” (in Russian), Nauka, Minsk (1988), p. 52.

G. D. Semchenko, A. V. Dunikov, I. N. Opryshko, et al., “Part II. Theoretical foundations of low-temperature synthesis of SiC from gels and practical realization of this process in the technology of ceramics and refractories. 1. Physicochemical foundations of low-temperature synthesis of SiC in heat treatment of gels,”Ogneup. Tekh. Keram., No. 10, 8 – 15 (1999).

G. D. Semchenko, “Part I. Fabrication of binders for ceramic production by the sol-gel method. 5. Fabrication and physico-chemical features of developed ethylsilicate binders for ceramic and refractory industries,”Ogneup. Tekh. Keram., No. 8, 2 – 6 (1999).

Author information

Authors and Affiliations

Additional information

Translated from Ogneupory i Tekhnicheskaya Keramika, No.7, pp.10 – 18, July, 2000.

Rights and permissions

About this article

Cite this article

Semchenko, G.D. A new direction in the creation of ceramic materials with a specified phase composition and structure. Part II. Theoretical foundations of low-temperature synthesis of SiC from gels and practical realization of this process in the technology of ceramics and refractories. 4. Mechanism of phase formation in the Al2O3 - SiC - Si - Pitch - ETS - H3BO4 system in the production of corundum refractories. Refract Ind Ceram 41, 220–227 (2000). https://doi.org/10.1007/BF02693753

Issue Date:

DOI: https://doi.org/10.1007/BF02693753