Abstract

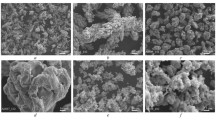

We examine the nature of the changes that occur in the microstructure and properties of fine-grained iron-copper composites with 30 mass % (27.3 vol. %) Cu during solid-phase heat treatment and when passing through the melting point of copper. Quantitative studies of the microstructure were made during sintering of mixtures of the highly dispersed powders of the initial metals and during heating of sintered high-density fine-grained specimens. The process of microstructure transformations during liquid-phase sintering and heating of high-density fine-grained composites above the melting point of copper was found to have three stages: recovery of the crystal structure and formation of large-angle boundaries in the Fe component, an increase in Fe grain size, and formation of solid solutions by mutual diffusion of components; penetration of the liquid phase along Fe grain boundaries with a decrease in grain size because of disintegration; and a secondary growth of Fe grains and formation of a Cu matrix structure or, more likely, a matrix structure of solid solution of Fe in Cu begins to form.

Similar content being viewed by others

References

Iain LeMay and L. McDonald Schetky (eds.),Copper in Iron and Steel, Wiley, New York (1982).

R. M. German, “The microstructure of liquid phase sintered materials,” in: R. N. German, R.J. Messing, and R. J. Cornwall (eds.),Sintering Technology, Dekker, New York (1995), pp. 213–220.

V. V. Panichkina and N. I. Filippov, “The influence of the small diffusion flows on the microstructure transformation in the fine-grained W — Cu and Fe — Cu pseudoalloys”,Functional Materials, No. 2, 274–278 (1999).

P. Ya. Radchenko, V. V. Panichkina, O. G. Radchenko, and V. V. Skorokhod, “Densification processes during sintering of fine-grained iron-copper pseudoalloys,”Poroshk. Metall., Nos. 1–2, 22–28 (2000).

V. V. Skorokhod, “Theory of the physical properties of porous materials and composites and the principles of controlling their microstructure in technological processes,”Poroshk. Metall., Nos. 1–2, 53–71 (2000).

K. Tabbeshfar and G. A. Chadwick, “Dimensional changes during liquid phase sintering of Fe — Cu compacts,”Powder Met.,27, No. 1, 19–24 (1984).

Author information

Authors and Affiliations

Additional information

Translated from Poroshkovaya Metallurgiya, Nos. 5–6(413), pp. 13–20, May–June, 2000.

Rights and permissions

About this article

Cite this article

Radchenko, O.G., Get’man, O.I., Radchenko, P.Y. et al. Nature of changes in the microstructure and properties of fine-grained iron-copper composites under heat treatment. Powder Metall Met Ceram 39, 225–231 (2000). https://doi.org/10.1007/BF02684672

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02684672