Abstract

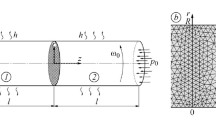

The temperature pattern is simulated at the contact between two metal particles during pulse sintering with rolling. Mathematical expressions are given for the solid-phase and liquid-phase processes.

Similar content being viewed by others

References

V. I. Spitsyn and O. A. Troitskii,Electroplastic Deformation of Metals [in Russian], Nauka, Moscow (1985).

A. I. Raichenko,Principles for Sintering Powders by Passing Electric Current [in Russian], Metallurgiya, Moscow (1987).

I. M. Mal’tsev, V. G. Petrikov, and L. A. Pyryalov, “Authors’ Certificate USSR 1748943, A Method for Electropulse Sintering of a Metal Powder and an Apparatus for Performing It” [in Russian], published 1993.

I. M. Mal’tsev and V. G. Petrikov, “An apparatus for electropulse sintering of a conducting powder during rolling,”Poroshk. Metall., No. 3, 100–103 (1993).

I. M. Mal’tsev and V. G. Petrikov, “Electropulse heating of a powder at a deformation cointainment volume during rolling,”Poroshk. Metall., No. 6, 38–41 (1993).

I. M. Mal’tsev and V. G. Petrikov, “Effects of isothermal annealing on the properties of powder-rolled alloys in the Fe — Cr — Ni system,”Poroshk. Metall., Nos. 11–12, 79–84 (1994).

L. O. Andrushchik, Yu. V. Kornyushin, and S. P. Oshkaderov, “Formation of interparticle connections in the electrocontact sintering of metal powders,”Metallofizika,13, No. 10, 110–121 (1991).

V. V. Meshkov, N. K. Myshkin, and A. I. Sviridenok, “A method of using technological parameters in the electrical sintering of conducting powders,”Poroshk. Metall., No. 3, 36–39 (1984).

I. N. Orlov,Electrotechnical Handbook in 5 Volumes [in Russian], Nauka, Moscow (1985)

Handbook of Thermophysical Properties of Solid Materials, McMillan Company, New York (1961).

G. D. Burdun, N. V. Kalashnikov, and L. R. Stotskii,The International System of Units [in Russian], Vyssh. Shk., Moscow (1964).

M. Yu. Bal’shin and S. S. Kiparisov,The Principles of Powder Metallurgy [in Russian], Metallurgiya, Moscow (1978).

I. V. Kudryavtsev (general editor),Engineering Materials Handbook, in 5 Volumes [in Russian], Mashinostroenie, Moscow (1967).

G. M. Zhdanovich,Theory of Metal Powder Pressing [in Russian], Metallurgiya, Moscow (1968).

S. T. S. Al-Hasani, “Electric discharge powder consolidation,” in:High Technology Processes in Powder Metallurgy [in Russian], Vysheish. Shk., Minsk (1982), pp. 81–89.

A. V. Pilipchenko, V. Ya. Belousov, A. I. Tsitrin, and A. N. Khomchenko, “Simulating the temperature pattern in the direct electrical heating of a powder material,”Poroshk. Metall., No. 10, 65–68 (1988).

Author information

Authors and Affiliations

Additional information

Translated from Poroshkovaya Metallurgiya, Nos. 5–6(413), pp. 5–12, May–June, 2000.

Rights and permissions

About this article

Cite this article

Mal’tsev, I.M. Simulating the temperature pattern at the contact between two metal particles during rolling with induction heating. Powder Metall Met Ceram 39, 218–224 (2000). https://doi.org/10.1007/BF02684671

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02684671