Abstract

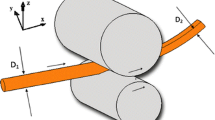

Published data are analyzed for the rolling technology of copper powder. It is established that production parameters for manufacturing copper rolled product are predetermined by the preparation method, chemical composition, shape and size of the original powder, the type of rolling equipment, and also the intended use of the final product.

Similar content being viewed by others

References

G. A. Vinogradov, Yu. N. Semenov, O. A. Katrus, and O. A. Katashinskii,Rolling of Metal Powders, M. Z. Ermanyuk (ed.) [in Russian], Metallurgiya, Moscow (1969).

D. Hunt and R. I. Eberall, “Production of parts from copper powders,”Powder Met., No. 8, 52–57 (1959).

D. A. Evans, “Rolling of copper powder,” in:Second Conf of Metallurgists, Quebec City (1963).

K. V. Savitskii, V. N. Zhdanova, A. P. Savitskii, et al., “Dependence of copper powder mechanical properties on porosity,”Izv. Vyssh Uchebn. Zaved. Fiz., No. 11, 57–63 (1962).

A. N. Nikolaev and Yu. N. Shlyutkin, “Study of hot rolling of copper and nickel powder billets,”Poroshk. Metall., No. 6, 25–28 (1968).

R. K. Dube, “Particle technology method for making metal strip. Part 3,”Powder Met. Int.,14, No. 2, 108–111 (1982).

O. A. Katrus, R. L. Oganyan, and A. P. Savitskii, “Study of physicomechanical properties and microstructure of compaction rolled product from copper powder,”Poroshk. Metall., No. 10, 15–21 (1968).

S. Bhargava and R. K. Dube, “Hot rolling of porous metal strips,”Zesz. Nauk Agh. Met. Jodlew., No. 110, 58–64 (1987).

D. I. Suchkov,Copper and its Alloys [in Russian], Metallurgiya, Moscow (1967).

O. A Katrus, A. V. Aleshina, and A. V. Perepelkin, “Study of the physicomechanical properties and microstructure of copper powder rolled products,”Poroshk. Metall., No. 11, 64–68 (1974).

O. A. Katrus, A. V. Aleshina, and Z. P. Vikarevich, “Study of hydrogen embrittlement for copper powder rolled product,”Poroshk. Metall., No. 7, 61–64 (1976).

V. A. Kolachev,Hydrogen Embrittlement of Nonferrous Metals [in Russian], Metallurgiya, Moscow (1966).

L. S. Moroz and N. N. Kolchatin, “Deformation of copper with small impurity contents,”Fiz. Met. Metalloved.,16, No. 5, 73–78 (1963).

E. G. Sychev and Yu. L. Bobarikin, “Inventor’s Cert. 1616786 USSR: Method for rolling thin metal strip from powder,” Publ. 12.30.90.

S. M. Romanov, “Study of the stress-strained state with rolling of copper powder,”Izv. Vyssh. Uchebn. Zaved. Met., No. 1, 25–28 (1995).

Author information

Authors and Affiliations

Additional information

Translated from Poroshkovaya Metallurgiya, Nos. 3/4(412), pp. 110–116, March–April, 2000.

Rights and permissions

About this article

Cite this article

Derkacheva, G.M., Kalutskii, G.Y. & Minakova, R.V. Copper powder rolling technology (review). Powder Metall Met Ceram 39, 202–206 (2000). https://doi.org/10.1007/BF02678645

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02678645