Abstract

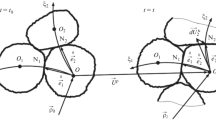

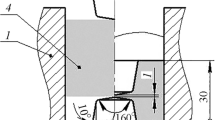

An experimental-computational method is developed to study the stress state of a material on the basis of its experimental kinematic diagram by using the techniques of visioplasticity. The method of R-functions and the method of stress functions are used in calculating the stress state. Volumetric plastic deformation is also taken into account. The stress field for the initial (nonsteady) stage of extrusion of an axisymmetric porous semifinished product is obtained.

Similar content being viewed by others

References

I. P. Renne,Experimental Methods of Studying Plastic Deformation in Metal-Shaping Operations by Using Indexing Grids [in Russian], Tula Polytechnic Institute, Tula (1970).

G. D. Del’ and N. A. Novikov,Method of Indexing Grids [in Russian], Mashinostroenie, Moscow (1974).

V. A. Ogorodnikov,Evaluating the Deformability of Metals During Shaping [in Russian], Vishcha Shk., Kiev (1983).

M. A. Rvachev and V. D. Pokras, “Use of the method ofR-functions to experimentally study stress state and deformability in axisymmetric metal-shaping operations,”Izv. Vyssh. Uchebn. Zaved. Chern. Metall., No. 11 (1991).

M. A. Rvachev, V. D. Pokras, and D. V. Sakharov, “‘Field-TDT’ system for solving boundary-value problems of the mechanics of deformable bodies on the basis of the method ofR-functions,” in:Mathematical Modeling of Metal-Shaping Operations: Summary of an International Conference, Perm (1987), pp. 96–97.

M. B. Shtern, G. G. Serdyuk, L. V. Maksimenko, et al.,Phenomenological Theories of the Pressing of Powders [in Russian], Nauk. Dumka, Kiev (1982).

V. A. Ogorodnikov, V. D. Sakharov, V. A. Matviichuk, and I. O. Sivak, “Study of the plastic deformation of porous material PZh4M2 and its deformability in rotational processes with a local deformation zone,”Izv. Vyssh. Uchebn. Zaved. Chern. Metall., No. 1, 52–55 (1991).

Author information

Authors and Affiliations

Additional information

Translated from Poroshkovaya Metallurgiya, Nos. 3–4(412), pp. 10–21, March–April, 2000.

Rights and permissions

About this article

Cite this article

Sakharov, D.V., Sivak, I.O., Pokras, V.D. et al. Peculiarities of use of the method of visioplasticity to determine the stress state of porous semifinished products. Powder Metall Met Ceram 39, 122–130 (2000). https://doi.org/10.1007/BF02678632

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02678632