Abstract

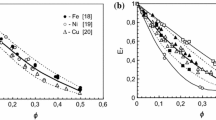

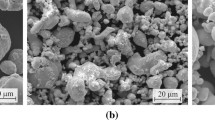

A plasticity criterion is proposed for powdered materials to account for the local character of slip and plastic deformation of the particles. The degree of localization of the contact interaction between the particles is quantitatively evaluated by using the relative fraction of the active volume, after M. Yu. Balshin. Good agreement is obtained between the theoretical and experimental data in describing of the process of the isostatic pressing of spherical powders of lead and tin. The effect of the density of the material and pressure on the form of the yield surface and the character of the volume deformation is examined. A method is presented for determination of the empirical parameters of the plasticity criterion. These parameters are evaluated for sand.

Similar content being viewed by others

References

V. V. Skorokhod and L. I. Tuchinskii, “Plasticity condition for porous bodies,”Poroshk. Metall., No. 11, 83–87 (1978).

M. B. Shtern, “Development of a theory of the pressing and plastic deformation of powdered materials,”Poroshk. Metall., No. 9, 12–24 (1992).

Ya. E. Beigel’zimer, A. P. Getmanskii, and L. I. Alistratov, “Plasticity condition for powders of hard-alloy mixtures,”Poroshk. Metall., No. 12, 11–15 (1986).

I. F. Martynova, V. V. Skorokhod, and S. M. Solonin, “Plastic deformation in the pressing of powders of ductile metals,”Poroshk. Metall., No. 3, 40–46 (1974).

M. Yu. Balshin,Scientific Principles of Powder Metallurgy and the Metallurgy of Fibers [in Russian], Metallurgiya, Moscow (1972).

V. D. Kal’ner, B. I. Beilin, and Ya. V. Shubert, “Features of the mechanism of the cold plastic deformation of sintered iron,”Metalloved. Term. Obrab. Met., No. 10, 2–5 (1982).

Ya. Be. Beigel’zimer and A. P. Getmanskii, “Model of development of the plastic deformation of porous bodies in a flow-theory approximation,”Poroshk. Metall., No. 10, 17–20 (1988).

P. I. Stoev, I. I. Papirov, G. F. Tikhinskii, and A. A. Vasil’ev, “Diagrams of the isostatic pressing of beryllium,”Fiz. Met. Metalloved.,78, No. 1, 9–19 (1994).

A. M. Laptev and S. V. Podlesnyi, “Calculation of force characteristics of the process of consolidating spherical powders,”Poroshk. Metall., No. 12, 11–17 (1985).

V. M. Segal, V. I. Reznikov, V. F. Malyshev, and V. I. Solov’ev, “Consolidation of powdered materials during hydrostatic loading,”Poroshk Metall., No. 6, 26–30 (1979).

A. F. Fedotov, “Characteristics of the plastic deformation and internal friction of bulk materials of a heat-insulating sheath for pressing SHS products,”Ogn. Tekh. Keramika, No. 7, 14–17 (1997).

Author information

Authors and Affiliations

Additional information

Translated from Poroshkovaya Metallurgiya, Nos. 3–4(412), pp. 4–10, March–April, 2000.

Rights and permissions

About this article

Cite this article

Amosov, A.P., Fedotov, A.F. Variant of the plasticity condition for powdered solids. Powder Metall Met Ceram 39, 116–121 (2000). https://doi.org/10.1007/BF02678631

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02678631