Abstract

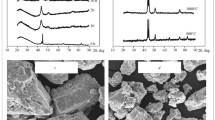

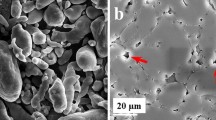

An investigation was made of the phase and structure transformations in compacts of high-speed steel R6M5F3 powder fractions −630+50 μm at the temperatures of solid-phase (1160–1220°C) and liquid-phase (1240°C) sintering. The structure of the compacts was crystalline or quasicrystalline, depending on the degree of superheating and cooling rate of the melt during powder spraying. This was related to the presence of a cellular structure in particles of a critical size in the powder. Compacts of powder with the cellular structure experienced higher shrinkage during solid-phase sintering as a result of structre relaxation and recrystallization. The driving force of these processes is the change in chemical potential arising from the decomposition of highly supersaturated metastable solid solutions, and the excess grain-boundary energy of the quasicrystalline matrix structure.

Similar content being viewed by others

References

I. S. Miroshnichenko,Quenching From the Liquid State [in Russian], Metallurgiya, Moscow (1982).

V. V. Skorokhod and S. M. Solonin,Physical-Metallurgical Principles of Powder Sintering [in Russian], Metallurgiya, Moscow (1984).

B. V. Khaenko, S. Ya. Golub, A. S. Fomichev, et al., “Composition and structure of the products of impactcentrifugal atomization of high-speed steels”,Poroshk. Metall., Nos. 9–10, 1–9 (1993).

S. A. Firstov, S. Ya. Golub, L. D. Kulak, and A. S. Fomichev, “A new iron-based metastable phase formed by super-high-speed solidification of high-alloy steels”Fiz. Met. Metalloved.,65, No. 4, 772–775 (1988).

V. E. Vaganov, I. V. Sharokhin, et al., “Production of rapidly cooled powders and compacts of a Fe−Cr−Mo−C wear-resistant alloy by powder metallurgy methods”, in:Powder Metallurgy High-speed Steels [in Russian], Inst. Probl. Materials Sci., Akad. Sci. Ukrainian SSR, Kiev (1990), pp. 32–36.

E. V. Arsheva, O. S. Yakushev, and L. M. Snagovskii, “Structure formation in the super-high-speed solidification of high-speed steels”, Inst. Probl. Materials Sci., Akad. Sci Ukrainian SSR, Kiev (1990), pp. 29–32.

L. A. Posnyak, V. I. Ul’shin, K. A. Gogaev, et al., “Structure and mechanical properties of high speed steels obtained from highly dispersed powders”, in:Structure, Defects, and Properties of Ultradispersed Quasicrystalline and Amorphous Materials [in Russian], V All-Union Seminar, Institute of Metal Physics, Academy of Sciences SSSR, Sverdlovsk (1990).

K. A. Gogaev, V. I. Ul’shin, Yu. N. Podrezov, et al., “Sintering behavior of high-speed steel R6M5F3 powder compacts” in:Powder Metallurgy Tool Steels [in Russian], Institute for Problems of Materials Science, Ukraine National Academy of Sciences, Kiev (1992), pp. 4–11.

L. A. Posnyak, V. I. Ul’shin, K. A. Gogaev, et al., “Formation of the structure and properties of powder metallurgy high-speed steels R6M5K5 and R6M5F3 during sintering and heat treatment”,Poroshk. Metall. No. 9, 79–83 (1991).

M. Kh. Shorshorov and T. A. Chernyshova, “Dependence on fraction of the mechanical properties and structure of high-speed steel 10R6M5 powder”,Fiz. Khim. Obrab. Mater., No. 4, 118–123 (1984).

L. A. Poznyak, Yu. V. Sorokin, and G. S. Ershov, “Heat treatment of melts in the production of atomized high-speed steel powders”,Poroshk. Metall., Nos. 11–12, 100–106 (1993).

A. K. Petrov, E. N. Smirnova, I. Ya. Kondratova, and L. V. Ocheretova, “Effect of particle size on the properties of sprayed high-speed steel powders and the compacts prepared from them”,Poroshk. Metall., No. 5, 18–23 (1976).

A. K. Petrov, I. S. Miroshnitchenko, V. V. Parabina, et al., “Investigation of the solidification of metal powders obtained by spraying from the liquid phase”,Poroshk. Metall., No. 1, 16–20 (1973).

L. A. Poznyak, V. I. Ul’shin, K. A. Gogaev, et al., “Effect of sintering regime on the structure and properties of high-speed steel obtained from powders of small particle size”, in:Materials of the VI International Congress on Heat Treatment, Moscow (1990), Vol. 5, pp. 77–83.

N. N. Buinov and R. R. Sakharova,Decomposition of Metallic Solid Solutions [in Russian], Metallurgiya, Moscow (1964).

O. A. Kaibyshev and R. Z. Valiev,Grain Boundaries and Properties of Metals, Metallurgiya, Moscow (1987).

B. I. Butakov, Yu. A. Bazin, and B. A. Baum,Investigation of the Effect of Hydroelectric Impulse Treatment on the Physical Properties of Metallic Melts [in Russian], Nauk. Dumka, Kiev (1992).

K. A. Gogaev, L. G. Shtyka, L. A. Poznyak, and V. I. Ul’shin, “Structural superplasticity in high-speed steels”,Poroshk. Metall., Nos. 9–10, 18–23, (1993).

L. A. Poznyak, V. I. Ul’shin, K. A. Gogaev, et al., “Production and efficiency of use of end cutting tool made from powder metallurgy high-speed steel”, in:New Technologies and Materials in Heavy Industry [in Russian], Kiev (1991), pp. 61–66.

“Tool life testing in milling”,ISO 8588-2, Publ. 1989.

“Comparative tests of high-speed steel cutters obtained by powder metallurgy”, Institute of Manufacturing Technology, Budapest (1991).

Additional information

Institute for Problems of Materials Science, Ukraine National Academy of Sciences, Kiev. Translated from Poroshkovaya Metallurgiya, Nos. 11–12(410), pp. 44–53, November–December, 1999.

Rights and permissions

About this article

Cite this article

Ul’shin, V.I., Poznyak, L.A. & Ul’shin, S.V. Phase and structure changes during the sintering of compacts of high-speed steels obtained from powders with various rates of solidification. Powder Metall Met Ceram 38, 572–578 (1999). https://doi.org/10.1007/BF02676189

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02676189