Abstract

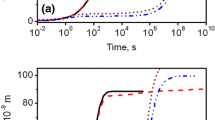

Some aspects of gradient structure development in cemented carbides at microscopic and submicroscopic levels are considered. The gradient structures are shown to develop mainly due to the nonequilibrium process of the liquid phase mass transfer in cemented carbides. Particular emphasis is placed on the theoretical and experimental description of the process of treatment with metal melts which allows the gradient structures at microscopic and submicroscopic levels to be obtained.

Similar content being viewed by others

References

D. W. Haglung, “Rock drill cutting insert of hard metal,”Pat. 2,842,342 USA, Publ. Jule 8, 1958.

M. N. Dovbishchuk, V. K. Vitrjanjuk, A. N. Krushinskii, et al., “Study of the possibility of making carbide articles possessing variable physico-mechanical properties,”Poroshk Metall., No 9, 37–41 (1966).

V. I. Tretyakov, T. A. Emelyanova, S. A. Dubinskii, et al., “Migration of the binding phase in articles of WC—CO hard alloys,”Tverd. Splavy Tugoplavkie Met. No 14, 80–86 (1973).

A. F. Lisovsky, “The migration of metal melts in sintered composite materials,”Int. J. Heat Mass Transfer,33, No 8, 1599–1603 (1990).

A. F. Lisovsky, “Some problems on tecnical use of the phenomenon of metal melts imbibition by sintered composites,”Powder Metall. Int.,21, No 6, 7–9 (1989).

A. F. Lisovsky, “On formation of nonequilibrium dihedral angles in composite materials,”Int. J. Powder Metall.,26, No 1, 45–49 (1990).

V. P. Bondarenko and A. F. Lisovsky, “Capillary welding of sintered carbides,”Poroshk. Metall., No 8, 28–33 (1973).

A. F. Lisovsky and N. V. Tkachenko, “Development of gradient structures in sintered carbides,”Sverkhtverd. Mater.,17, No. 1, 27–34 (1995).

C. Colin, L. Durant, N. Favrot, et al., “Processing of composition gradient WC—Co cerments,” in:Proc. of the 13-th Int. Plansee Seminar [Russian translation], Metallwork Plansee, Reutte, Vol. 2, 522–536 (1993).

A. F. Lisovsky, N. V. Tkachenko, and V. Kebko, “Structure of the binding phase in realloyed WC—Co cemented carbides,”Int. J. Refract. Met. Hard Mater.,10, No 1, 33–36 (1991).

A. F. Lisovsky and N. V. Tkachenko, “Composition and structure of cemented carbides produced by MMT-process,”Powder Metall. Int.,23, No 3, 157–161 (1991).

C. H. Vassel, A. D. Krawitz, E. F. Drake, et al., “Binder deformation in WC—(Co, Ni) cemented carbide composites,”Metall. Trans.,16A, 2309–2317 (1985).

A. F. Lisovsky and N. V. Tkachenko, “On the use of the MMI-phenomenon for the formation of nanostructures in WC—Co cemented carbides,”Int. J. Refract. Met. Hard Mater.,15, 227–235 (1997).

Additional information

Institute of Superhard Materials, Ukraine National Academy of Sciences, Kiev, Published in Poroshkovaya Metallurgiya, Nos. 11–12(410), pp. 15–20, November–December, 1999.

Rights and permissions

About this article

Cite this article

Lisovsky, A.F. Formation of gradient structures in cemented carbides. Powder Metall Met Ceram 38, 545–549 (1999). https://doi.org/10.1007/BF02676184

Issue Date:

DOI: https://doi.org/10.1007/BF02676184