Abstract

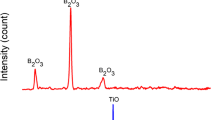

The sintering behavior in vacuum of ultrafine nonmilled titanium boride powder and a composite of the latter with CaB6 was investigated. It was shown that such titanium boride powders and TiB2−CaB6 composites poses better sinterability than conventional powders; the temperature of rapid densification was approximately 200°C lower. The introduction of ∼1% each of Fe and Ni into the TiB2−5% CaB6 composite noticeably accelerated densification due to the formation of a transient liquid phase. The effect was further enhanced by the activation of surface and volume diffusion by the solution of Fe and Ni in TiB2, as well as recrystallization processes.

Similar content being viewed by others

References

P. S. Kislyi and M. A. Kuzenkova, Sintering of Refractory Compounds [in Russian], Nauk, Dumka, Kiev (1980).

T. I. Serebryakova, V. A. Neronov, and P. D. Peshev, High Temperature Borides [in Russian], Metallurgiya, Chelyabin. Otd-nie, Moscow (1991).

R. L. Coble, J. Amer. Ceram. Soc.,56, No. 9, 461–466 (1973).

V. V. Skorokhod, “Theory of relaxation and creep of distorted metal crystals,” Poroshk. Metall., No. 3, 54–58 (1966).

V. M. Gropyanov, “Activated sintering of highly refractory materials,” in: Theory and Practice of Sintering [in Russian], Nauk. Dumka, Kiev (1974), pp. 185–192.

P. S. Kislyi and M. A. Kuzenkova, “On the mechanism of shrinkage of zirconium diboride during sintering,” Poroshk. Metall., No. 2, 46–55 (1966).

P. S. Kislyi and M. A. Kuzenkova, “Sintering refractory compounds of variable composition,” ibid.,, No. 2, 38–43 (1973).

T. I. Serebryakova, “Prospective developments in the field of boride synthesis,” in: Borides, Kiev (1990), pp. 4–27.

M. V. Vlasova, T. I. Serebryakova, and B. I. Lyashenko, “Space-structural aspects in the formation of dispersed TiB2 powders by the carbothermic reduction of oxides,” ibid., Borides, Kiev 62–69 (1994).

C. B. Finch and P. F. Becher, Adv. Ceram. Mater.,1, No. 1, 50–54 (1986).

W. A. Zdanewski, J. Amer. Cer. Soc.,70, No. 11, 793–797 (1987).

J. R. Ramberg, C. F. Wolfe, and W. S. Williams, ibid.,,68, No. 3, 78–79 (1985).

Additional information

Deceased.

Materials Science Institute, Ukrainian Academy of Sciences, Kiev. Translated from Poroshkovaya Metallurgiya, Nos. 11–12, pp. 16–21, November–December, 1997.

Rights and permissions

About this article

Cite this article

Serebryakova, T.I., Martynenko, E.N. Sintering of highly dispersed titanium diboride and composite titanium diboride-calcium hexaboride powders. Powder Metall Met Ceram 36, 579–583 (1997). https://doi.org/10.1007/BF02676142

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02676142