Abstract

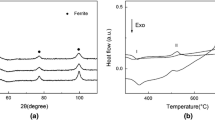

The advantages of low-alloy sintered materials produced from iron—copper master alloy are confirmed. Physical and technological properties of the master alloy powders are determined. Experiments show that mixtures of iron, graphite, and iron—copper powders compact well to produce high-quality articles. Sintered materials have strength values (σf ∼ 345 MPa, HB ∼ 1430 MPa) comparable with those of similar materials produced using electrolytic copper.

Similar content being viewed by others

References

P. N. Ostrik, M. M. Gasik, and V. D. Pirog, Metallurgy of Sponge and Powder Master Alloys [in Russian], Tekhnika, Kiev (1992).

M. Hansen and K. Anderko, Structure of Binary Alloys: Handbook [Russian translation], Metallurgiya, Moscow (1962).

A. A. Silaev and B. D. Fishman, Dispersion of Molten Metals and Alloys [in Russian], Metallurgiya, Moscow (1983).

V. B. Akimenko, B. Ya. Bulanov, V. V. Rukin, et al., Iron Powders [in Russian], Nauka, Moscow (1982).

V. Shatt (ed.), Powder Metallurgy. Sintering and Composite Materials [Russian translation], Metallurgiya, Moscow (1983).

Additional information

Ukraine State Metallurgical Academy, Dnepropetrovsk. Translated from Poroshkovaya Metallurgiya, Nos. 11–12, pp. 1–4, November–December, 1997.

Rights and permissions

About this article

Cite this article

Svinolobova, I.N., Ostrik, P.N. & Kovzik, A.N. Properties of iron-copper master alloy powder. Powder Metall Met Ceram 36, 567–569 (1997). https://doi.org/10.1007/BF02676139

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02676139