Abstract

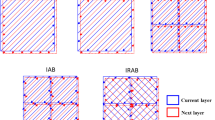

A classification is presented for schemes for rolling powders in terms of the homogeneity condition for strain in the feed zone. The minimal deformation occurs on supply to one of the rolls, when the thickness of the powder flow is less than the feed area. As the feed is to two rolls and is accompanied by maximum strain on account of the aggregate-block mechanism, the macrodefects that are formed in the feed zone are inherited by the product. The operations are detailed in selecting the rolling parameters D, B, and \gaf to provide stable formation of a porous product with given thickness and density, which are affected by the grain-size composition and poured density. A stable grading is provided if the roll roughness is constant, as are the geometrical conditions of the process, which is operated in the optimal speed range. The density homogeneity of the product is improved as the connectedness of the powder decreases and as the ratio hp/dp increases.

Similar content being viewed by others

References

G. I. Aksenov, A. N. Nikolaev, and Yu. N. Semenov, “Rolling a powder into a strip,” in: Aspects of Powder Metallurgy and Metal Strength [in Russian], Izd. AN Ukr. SSR, Kiev,2, 119–140 (1955).

O. A. Katrus, “Spreading in powder rolling,” Poroshk. Metall., No. 2, 17–23 (1980).

E. B. Vernik and O. A. Katrus, “The effects of roll roughness on powder rolling,” ibid.,, No. 7, 15–21 (1974).

O. A. Patrus, “Critical velocities in powder rolling,” ibid.,, No. 1, 34–40 (1978).

O. A. Katrus, R. L. Oganyan, and V. N. Artem'ev, “Determining gas permeability for metal powders,” ibid.,, No. 10, 1–3 (1970).

A. M. Musikhin and G. A. Vinogradov, “High-speed metal powder rolling,”. ibid., Poroshk. Metall., No. 6, 17–24

G. I. Aksenov and V. P. Revyakin, “Accelerating the rolling of metal powders,” ibid.,, No. 3, 32–37 (1969).

G. I. Aksenov, “Effects of air on powder rolling conditions,” in: Abstracts for the 6th Conference on Powder Metallurgy [in Russian], Moscow (1962), pp. 14–19.

G. A. Vinogradov, Research on Metal Powder Rolling: DSc Thesis [in Russian], Kiev (1963).

P. E. Evans, “The theoretical optinum rolling speed in powder compaction,” in: Modern Developments in Powder Metallurgy, Vol. 1, Plenum Press, New York (1966), pp. 247–252.

P. E. Evans, “The maximal powder rolling rate: A theoretical and experimental study,” in: Modern Developments in Powder Metallurgy, Vol. 4, Plenum Press, New York and London (1971), pp. 549–593.

O. A. Katrus and V. M. Ocheretyanskii, “An analysis of air movement in powder rolling,” Poroshk. Metall., No. 2, 28–30 (1984).

G. A. Vinogradov and V. P. Katashinskii, Theory of Sheet Rolling for Metall and Granules [in Russian], Metallurgiya, Moscow (1979).

O. A. Katrus, “Longitudinal strain in powder rolling,” Poroshk. Metall., No. 9, 5–10 (1984).

O. A. Katrus, “Calculating parameters for strip rolling from powders from the poured density,” ibid.,, No. 2, 9–15 (1981).

O. A. Katrus and A. K. Radchenko, “Effects of roll roughness and relative powder density on product thickness and density,” ibid.,, No. 12, 13–17 (1983).

G. A. Vinogradov, Yu. N. Semenov, O. A. Katrus, and V. P. Katashinskii, Rolling Metal Powders [in Russian], Metallurgiya, Moscow (1969).

O. A. Katrus and V. K. Gribkov, “Aggregate-structure parameters for powders in the incoherent zone on rolling,” Poroshk. Metall., No. 7, 23–31 (1979).

O. A. Katrus, “Strain macromechanism in the incoherent zone on rolling,” ibid.,, No. 9, 1–7 (1982).

O. A. Katrus, “A stochastic mechanism for the formation of a powder body in the incoherent zone on rolling,” ibid.,, No. 6, 19–25 (1978).

K. M. Radchenko, Theory of Rolling Sintered Strips [in Russian], Naukova Dumka, Kiev (1976).

Additional information

Institute for Materials Science Problems, Ukrainian Academy of Sciences, Kiev. Translated from Poroshkovaya Metallurgiya, Nos. 3–4, pp. 52–58, March–April, 1997.

Rights and permissions

About this article

Cite this article

Katrus, O.A. Production of semifinished items with set sizes and density on rolling powders. Powder Metall Met Ceram 36, 164–169 (1997). https://doi.org/10.1007/BF02676083

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02676083