Abstract

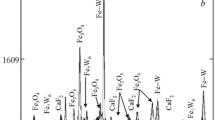

The tribological properties of ceramic composites of the system TiN−AlN are studied in the concentration range 10–90% AlN. It was found that materials which contain 25, 50, and 75% AlN have a low friction coefficient. Their rate of wear when paired with steel is neglible—2.9–6.0 μm/km (the wear rate of a steel-steel 024 couple is 1000 μm/km). Thin oxide films are formed during friction at high velocities and pressures. These films have relatively high adhesion with respect to materials of the TiN−AlN system and relatively low adhesion with respect to steel. The films may act as a solid lubricant, thus reducing the friction coefficient and wear. This is particularly true of the materials 25% TiN−75% AlN and 50% TiN−50% AlN.

Similar content being viewed by others

References

E. T. Mamykin and A. I. Yuga, “Complex of machines and the methods for determining the anti-friction properties of materials during sliding friction,”Poroshk. Metall., No. 1, 67–72 (1973).

A. D. Panasyuk, L. I. Struk, A. I. Yuga, et al., “Tribological properties of ceramics based on nonmetallic nitrides,”Poroshk. Metall., No. 8, 76–81 (1990).

R. Tsudzi and K. Ibiden,Japanese Patent No. 61-281086. Materials for Rubbing Parts, Published 11.12.86.

O. N. Grigor’ev. T. V. Mosina, A. D. Panasyuk, and N. P. Brodnicovsky, “Development of TiN−AlN ceramics and investigations of their physico-mechanical properties,” in:Proceedings of the Fifth Conference of the European Ceramic Society, Versailles (1997), pp. 2044–2047.

V. O. Lavrenko, T. V. Mosina, O. M. Grigor’ev, and A. D., Panasyuk, “High-temperature oxidation of powders and composites of the system TiN−AlN,”Dopov. Nats. Akad. Nauk Ukrainy, No. 12, 139–143 (1997).

Additional information

Institute for Problems, of Mateirals Science, Ukraine National Academy of Sciences, Kiev. Translated from Poroshkovaya Metallurgiya, Nos. 9–10(109), pp. 104–108, September–October, 1999.

Rights and permissions

About this article

Cite this article

Mosina, T.V., Panasyuk, A.D., Yuga, A.I. et al. Friction properties of composites of the system TiN−AlN. I. Effect of structure and phase composition of friction and wear of materials of the system TiN−AlN. Powder Metall Met Ceram 38, 517–520 (1999). https://doi.org/10.1007/BF02676071

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02676071