Abstract

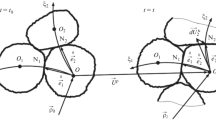

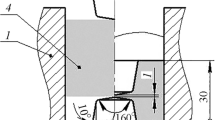

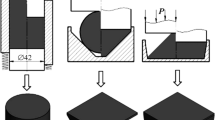

A numerical method is proposed for calculating the strain during hot open-die forming of porous preforms. With this model the density distribution in various stamping zones at any stage of the process can be estimated as a function of the preform size and the geometry of the empty die. The optimal parameters for the process can be chosen on the basis of the results.

Similar content being viewed by others

References

Yu. G. Dorofeev, B. G. Gasanov, V. Yu. Dorofeev, et al., Industrial Technologies for Hot Pressing of Powder Products [in Russian], Metallurgiya, Moscow (1990).

G. A. Baglyuk, S. N. Kaplya, G. E. Mazharova, and L. A. Poznyak, “Die for hot stamping of powder products,” Kuzn.-Shtamp. Proiz-vo, No. 8, 33 (1991).

Inventor’s Certificate 1282959 SSSR, “Equipment for stamping powder products,” Byull. Izobret., No. 2 (1987).

V. A. Pavlov, A. N. Lyashenko, and V. M. Anokhin, “Study of the compaction of titanium powder during hot stamping,” in: Research on Hot Pressing in Powder Metallurgy [in Russian], Novosibirsk (1984).

G. E. Mazharova, G. A. Baglyuk, and A. V. Dovydenkova, Manufacture of Products from Nonferrous Metal Powders [in Russian], Tekhnika, Kiev (1989).

G. A. Baglyuk, V. L. Yurchuk, and S. S. Kovalenko, “Application of variational methods in the calculation of pressure working of sintered preforms,” Fiz. Tekh. Vys. Davl., No. 24, 57 (1987).

M. B. Shtern, G. G. Serdyuk, L. A. Maksimenko, et al., Phenomenological Theories of Powder Pressing [in Russian], Nauk Dumka, Kiev (1982).

A. M. Laptev, “Variational functional for a rigid-plastic porous material,” Poroshk. Metall., No. 1, 1 (1983).

G. A. Baglyuk, “Power dissipation on the velocity discontinuity surfaces in a porous rigid-plastic material,” Fiz. Tekh. Vys. Dovl.,3, No. 3, 86 (1993).

L. I. Turchak, Fundamentals of Numerical Methods [in Russian], Nauka, Moscow (1987).

E. A. Olevskii, M. B. Shtern, G. G. Serdyuk, and O. V. Mikhailov, “Distribution density during pressing of products with a height transition,” Poroshk. Metall., No. 3, 15 (1989).

Additional information

Institute of Problems in Material Science, National Academy of Sciences of Ukraine, Kiev. Translated from Poroshkovya Metallurgiya, Nos. 7–8, pp. 1–7, July–August, 1997.

Rights and permissions

About this article

Cite this article

Baglyuk, G.A., Yurchuk, V.L. Calculation of the plastic flow of a porous material in open-die stamping. Powder Metall Met Ceram 36, 353–358 (1997). https://doi.org/10.1007/BF02675992

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02675992