Abstract

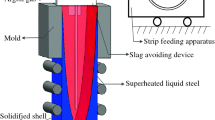

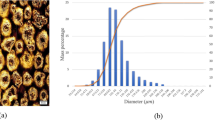

A process was experimentally and mathematically modeled for continuous and direct production of metal strip from its molten state by the use of Rheocasting. The process comprises 1) continuous production of a Rheocast semisolid alloy, and 2) direct shaping of the semisolid into strip. Sn-15 pct Pb was used as the modeling alloy. Crack formation and surface quality of the strip produced depend on fraction solid and deformation force. Continuous, sound strip could be obtained with good surface quality when fraction solid was between 0.50 and 0.70 and deformation force did not exceed a given maximum. Sheet thickness depends on deformation force, fraction solid, rotor rate of Rheocaster and production line speed. At constant deformation force, sheet thickness increases as fraction solid increases, rotor rate decreases and line speed is reduced. Sheet thickness is larger in the center than in the edge, but the difference is reduced by applying edgers. Some segregation of lead toward the edges is observed, and the segregation increases as amount of deformation is increased. A mathematical model for heat flow, solidification and deformation was constructed. The model predicts the point of completion of solidification in the strip and sheet thickness as a function of deformation force and line speed. Calculations are in good agreement with experimental results.

Similar content being viewed by others

References

J. Szekely: “Radically Innovative Steelmaking Technology”, Report submitted to Office of Technology Assessment, U.S. Congress, 1978.

C. J. Petry:Light Met. Age, 1975, vol. 33, no. 11–2, pp. 34–37.

G. Vassily:Light Met. Age, 1975, vol. 33, no. 11-12, pp. 5–8.

P. K. Raiford:Light Met. Age, 1975, vol. 33, pp. 16–22.

L. W. Collings, Jr., J. G. Donleavy, and O. J. Rassi:Nonferrous Wire Handbook, vol. 1, pp. 37–69, The Wire Association International Inc., Guilford, CT, 1977.

K. Tromel and G. Bollig: Canadian Patent No. 937381, November 27, 1973.

E. A. Mizikar, W. M. Wojcik, and K. Li: U.S. Patent No. 3,345,738, October 10, 1967.

D. B. Spencer, R. Mehrabian, and M. C. Flemings:Met. Trans., 1972, vol. 3, pp. 1925–32.

R. Mehrabian and M. C. Flemings:Trans. Am. Foundrymen’s Soc, 1972, vol. 80, pp. 173–82.

E. F. Fascetta, R. G. Riek, R. Mehrabian, and M. C. Flemings:Trans. Am. Foundrymen’s Soc, 1973, vol. 81, pp. 95–100.

K. P. Young, R. G. Riek, J. F. Boylan, R. L. Bye, B. E. Bond, and M. C. Flemings:Trans. Am. Foundrymen’s Soc, 1976, vol. 84, pp. 169–74.

R. G. Riek, K. P. Young, N. Matsumoto, R. Mehrabian, and M. C. Flemings: Paper No. G-T75-153, Eighth S.D.C.E. International Die Casting Exposition and Congress, Cobo Hall, Detroit, MI, March 17–20, 1975.

M. C. Flemings, R. G. Riek, and K. P. Young: Paper No. G-T77-P92, Society of Die Casting Engineers Exposition and Congress, Milwaukee, 1977.

R. A. Joly and R. Mehrabian:J. Mater. Sci., 1976, vol. 11, pp. 1393–1418. (R. A. Joly, Ph.D. Thesis, MIT, 1974.)

V. Laxmanan: Sc.D. Thesis, MIT, 1979.

DYSYS, MIT Joint Computer Facility, 1978.

J. H. Hockett:J. Iran Steel Inst., 1965, vol. 203, no. 1, pp. 27–35.

R. E. Gaskell:J. Appl. Mech., 1950, vol. 17, pp. 334–36.

I. Brazinsky, E. F. Cosway, C. F. Valle, J. R. C. Jones, and V. Story:J. Appl. Polym. Sci., 1970, vol. 14, pp. 2771–84.

W. W. Alston, Jr. and K. N. Still:J. Appl. Polym. Sci., 1973, vol. 17, pp. 3157–74.

C. Kiparissides and J. Vlachopoulos:Polym. Eng. Sci., 1976, vol. 16, pp. 712–719.

J. R. A. Pearson:Mechanical Principles of Polymer Heat Processing, p. 60, Pergamon Press, Oxford, 1966.

O. J. Kleppa:J. Phys. Chem., 1955, vol. 59, pp. 175–81.

D. R. Stull and H. Prophet: JANAF Thermochemical Tables, 2nd ed., NSRDS-NBS 37, Washington, D.C., 1971.

R. Hultgren, P. D. Desai, D. T. Hawkins, M. Gleiser and K. K. Kelley:Selected Values of the Thermodynamic Properties of the Elements, pp. 379–85 and 477–86, ASM, Metals Park, OH, 1973.

R. Hultgren, P. D. Desai, D. T. Hawkins, M. Gleiser, and K. K. Kelley:Selected Values of the Thermodynamic Properties of Binary Alloys, pp. 1265–69, ASM, Metals Park, OH, 1973.

D. G. Backman, R. Mehrabian, and M. C. Flemings:Met. Trans. B, 1977, vol. 8B, pp. 471–77.

B. E. Bond: Sc.D. Thesis, MIT, 1978.

Author information

Authors and Affiliations

Additional information

T. MATSUMIYA, formerly with Massachusetts Institute of Technology, Cambridge, MA.

Rights and permissions

About this article

Cite this article

Matsumiya, T., Flemings, M.C. Modeling of continuous strip production by rheocasting. Metall Trans B 12, 17–31 (1981). https://doi.org/10.1007/BF02674755

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02674755