Abstract

The absorption of gas through the plume eye and of an injected gas in a steelmaking ladle process was investigated, using a physical model of CO2 absorption into a NaOH solution. The results show that the inert gas escaping through the plume eye is ineffective in protecting the bath from the atmosphere, and placing an oil layer (simulated slag) decreases the absorption rate significantly. Increasing the flow rate of the inert gas not only exposes more of the liquid surface to the CO2 atmosphere, but also increases the mass transfer coefficient at the surface. The overall mass transfer between an injected CO2 gas and NaOH solution includes the mass transfer through the surface of the bath as well as the mass transfer in the bubble dispersion zone. The difference between the mass transfer in the bubble dispersion zone and the overall mass transfer was found to be significant for relatively low gas flow rates. The mass transfer coefficient of CO2 in the bubble dispersion zone was estimated using available information regarding the bubble size and velocity. Mass transfer coefficient estimated for the constant bubble frequency regime shows a dependence on gas flow rate. However, if a constant characteristic size of bubbles is assumed as an alternative approach, the mass transfer coefficient is independent of the gas flow rate.

Similar content being viewed by others

Abbreviations

- A :

-

interfacial area (cm2)

- C :

-

concentration in bulk (gr/cm3)

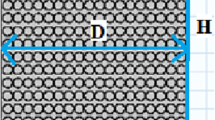

- D :

-

diffusivity (cm2/sec)

- L :

-

depth of liquid bath (cm)

- Q :

-

gas flow rate at STP (1/min)

- U :

-

velocity (cm/sec)

- V :

-

volume (1)

- d :

-

diameter (cm)

- k :

-

mass transfer coefficient (cm/sec)

- p :

-

partial pressure (atm)

- t :

-

time (min)

- B :

-

bubble

- T :

-

tuyere

- l :

-

liquid

- O :

-

initial state

- t :

-

reaction time

- v :

-

vessel

- w :

-

water phase

- eq:

-

equilibrium

References

Seon-Hyo Kim and R. J. Fruehan:Metall. Trans. B, 1987, vol. 18B, pp. 381–90.

R. J. Fruehan, B. Lally, and P. Glaws:Proc. Fifth International Iron and Steel Congress, April 6–9, 1986, Washington, DC, pp. 339–46,Trans. ISS, in press.

R. J. Fruehan and L. Martonik:Metall. Trans., 1974, vol. 5, pp. 1027–32.

P. C. Glaws and R. J. Fruehan:Metall. Trans. B, 1985, vol. 16B, pp. 551–59.

R. J. Fruehan:Ironmaking and Steelmaking, 1976, no. 1, pp. 33–37.

L. Davidson and E. Amick:AIChE J., 1956, vol. 2(3), pp. 337–42.

M. Sano and K. Mori:ISIJ Trans., 1980, vol. 20, pp. 675–81.

M. Sano, H. Makino, Y. Ozawa, and K. Mori:ISIJ Trans., 1986, vol. 26, pp. 298–305.

I. Leibson, E. Holcomb, A. Cacoso, and J. Jacmic:AIChE J., 1956, vol. 2(3), pp. 296–306.

S. Inada and T. Watanabe:ISIJ Trans., 1977, vol. 17, pp. 21–27.

R. J. Fruehan and L. J. Martonik:Proc. of Third International Iron and Steel Congress, April 16–20, 1978, Chicago, IL, pp. 229–37.

Y. Kato, T. Fijii, T. Saburaya, and Y. Habu:Tetsu-to-Hagané, 1983, vol. 69, p. s1011.

A. Kikuchi, S. Taniguchi, and N. Bessho:Proc. Fifth International Iron and Steel Congress, April 6–9, 1986, Washington, DC.

R. J. Fruehan:Metals Technology, March 1980, pp. 95–101.

P. Calderbank:Chemical Engineer, Oct. 1967, pp. 209–33.

P. Calderbank and M. Moo-Young:Chem. Eng. Sci., 1961, vol. 16, p. 39.

A. Svjazin, A. Sherchenko, and Y. Minaev:Scaninject III, #43, MEFOS and Jernkontoret, June 1983, Luleå, Sweden.

S. Inada and T. Watanabe:Tetsu-to-Hagané, 1975, vol. 61, p. s449.

N. Bessho, S. Taniguchi, and J. Kikuchi:Tetsu-to-Hagané, 1982, vol. 68, p. s125.

T. Toge, Y. Fujita, and K. Chizawa:Tetsu-to-Hagané, 1983, vol. 69, p. s873.

M. Kawakami, H. Ito, M. Okuyama, T. Kikuchi, and S. Sakase:Gakushin, Feb. 1983, No. 9-10468.

S. Takeuchi, N. Harada, H. Nakamura, T. Fujii, and Y. Habu:Gakushin, May 1984, No. 9-10565.

Seon-Hyo Kim: Ph.D. Thesis, Jan. 1987, Carnegie Mellon University, Pittsburgh, PA.

S. Inada and T. Watanabe:Tetsu-to-Hagané, 1976, vol. 62, pp. 807–16.

Y. Sahai and R.I.L. Guthrie:Metall. Trans. B, 1982, vol. 13B, pp. 193–202.

G. B. Dillon and I. J. Harris:The Canadian Journal of Chemical Engineering, Dec. 1966, pp. 307–12.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Kim, SH., Fruehan, R.J. Physical modeling of gas/liquid mass transfer in a gas stirred ladle. Metall Trans B 18, 673–680 (1987). https://doi.org/10.1007/BF02672883

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02672883