Abstract

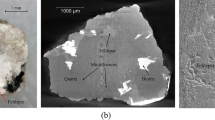

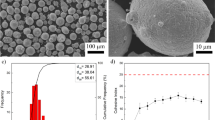

Cylindrical axisymmetric explosive consolidation with a pressure medium has been performed on fine irregular Ti powder. The effects of pressure medium on the consolidation process, micro-structural modifications, and tensile properties of the compacts were investigated. The pressure medium used in the present study was water. An optimum consolidation condition was deter-mined by changing the mass ratio of explosive to the innermost powder container tube plus consolidated powder(E/M ratio). For producing a sound compact, an optimumE/M ratio with-out a pressure medium is about 1.52. This narrow window of optimization is an inherent dis-advantage of the explosive consolidation without a pressure medium. On the contrary, an optimumE/M ratio with a pressure medium is determined to be from 1.80 to 5.14, where neither cracks nor central melt hole are formed in the compact. The presence of the pressure medium is ef-fective in extending the range of the optimumE/M ratio. The relative density (the percentage to the theoretical density) of an as-compacted specimen reaches 95 pct or more under the op-timum condition. Microstructural modifications show that substantial interparticle bonding is achieved by melting the surface of the powder or the powder itself. However, the ultimate tensile strength of an as-compacted specimen is 280 MPa with no ductility. The tensile properties of the compacts can be improved by postsintering treatments. The sintering under the optimum condition (1273 K/2 h) raises the ultimate tensile strength and the elongation to 750 MPa and 14 pct, respectively. The observed effect of postsintering treatment on tensile properties of the compacts can be consistently explained by the modification of microstructure.

Similar content being viewed by others

References

M.A. Meyers, B. Gupta, and L.E. Murr:J. Met., 1981, vol. 33 (10), pp. 21–26.

M.A. Meyers and H.R. Pak:J. Mater. Sci., 1985, vol. 20, pp. 2133–40.

P. Kasiraj, T. Veeland, Jr., R.B. Schwarz, and T.J. Ahrens:Acta Metall., 1984, vol. 32, pp. 1235–41.

T.C. Peng, S.M.L. Sastry, J.E. O’Neal, and D. Brasher:Metall. Trans. A, 1985, vol. 16A, pp. 1445–55.

K. Takashima, H. Tonda, M. Ueno, T. Toraishi, and M. Miyano:J. Iron Steel Inst. Japan, 1987, vol. 73, pp. 2219–26.

M.A. Meyers and S.L. Wang:Acta Metall., 1988, vol. 36, pp. 925–36.

T. Negishi, T. Ogura, T. Masumoto, T. Goto, K. Fukuoka, Y. Shono, and H. Ishii:J. Mater. Sci., 1985, vol. 20, pp. 399–406.

M. Mitono and N. Setaka:J. Mater. Sci., 1985, vol. 16, pp. 851–52.

K. Kondo, S. Soga, E. Rapoport, A. Sawaoka, and M. Araki:J. Mater. Sci., 1986, vol. 21, pp. 1579–90.

T. Akashi and A. Sawaoka:J. Mater. Sci., 1987, vol. 22, pp. 1127–34.

R. Prummer:Explosive Welding, Forming and Compaction, T.Z. Blazinski, ed., Applied Science Publishers Ltd., Barking, Essex, United Kingdom, 1983, pp. 369–95.

M.L. Wilkins:High Energy Rate Fabrication —J984, I. Berman and J.W. Schroeder, eds., ASME, New York, NY, 1984, pp. 63–69.

I. Fukuda, N. Nagayama, M. Fujita, and K. Kiyota:J. Industrial Explosive Soc. Japan, 1980, vol. 46, pp. 90–97.

A. Chiba, M. Nishida, T. Yamaguchi, and J. Tosaka:Scripta Metall., 1987, vol. 22, pp. 213–17.

N.E. Paton and W.A. Backofen:Metall. Trans. A, 1970, vol. 1, pp. 2839–47.

K. Majima, T. Isono, and K. Shoji:J. Jpn. Soc. Powder Powder Metall., 1986, vol. 33, pp. 28–33.

R.I. Jaffee, H.R. Ogden, and D.J. Maykuth:Trans. AIME, 1950, vol. 188, pp. 1211–66.

Author information

Authors and Affiliations

Additional information

formerly Graduate Students, Kumamoto University, are with Nippon Steel Corporation, Nagoya 476, and Kitakyushu 805, respectively, Japan.

Rights and permissions

About this article

Cite this article

Nishida, M., Chiba, A., Imamura, K. et al. Microstructures and mechanical properties of explosively consolidated Ti powder with a pressure medium. Metall Trans A 20, 2831–2839 (1989). https://doi.org/10.1007/BF02670175

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02670175