Abstract

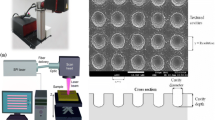

A pulsed CO2-TEA laser was used to melt the surface of plasma-sprayed coatings. An analysis of the laser parameters on the heat transfer is made: the melt depth and the surface temperature were calculated for different laser inputs. It was found that the pulse length must be in the range of 20 to 40 μs in order to fill up the pores of the coating and to keep the surface temperature below the boiling range. Experimental results on surface modification are explained in terms of power density.

Similar content being viewed by others

References

J. D. Ayers and R. J. Shaefer:Report of NRL Progress, May 1979, pp. 8–9.

R.J. Pangborn and D. R. Beaman:J. Appl. Phys., 1980, vol. 51, pp. 5992–93.

W. D. Murray and F. Landis:Trans. ASME, 1959, vol. 81, pp. 106–12.

W. L. Heitz and J. W. Westwater:Int. J. of Heat and Mass Transfer, 1970, vol. 13, pp. 1371–75.

T.W. Zavecz and M.S. Saifi.Appl. Phys. Lett., 1975, vol. 26 (4), pp. 165–68.

Y.S. Touloukian and D.P. Dewitt:Thermophysical Properties of Matter, Thermal Radiative Properties of Metallic Elements and Alloys, IFl/Plenum, New York, NY, 1970, vol. 7, pp. 413–62.

C. J. Smithells, ed.:Metals Reference Book, 5th edition, Butterworths, London, 1976, p. 945.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Dallaire, S., Cielo, P. Pulsed laser treatment of plasma sprayed coatings. Metall Trans B 13, 479–483 (1982). https://doi.org/10.1007/BF02667764

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02667764