Abstract

The origins of rhomboidity, longitudinal corner cracks, and breakouts in the continuous casting of steel billets have been investigated with the aid of heat flow and stress analyses of the mold wall. It has been shown that these problems can be linked to intermittent boiling in the cooling water channel, which may occur asynchronously on different faces of the mold. A mechanism based on asynchronous, intermittent boiling and nonsymmetrical cooling of the mold wall has been formulated which explains the influence of billet size, cooling-water velocity, water pressure, cold face roughness, and steel carbon content on the formation of rhomboidity and longitudinal corner cracks. Prevention of intermittent boiling is thereby shown to be a key factor in the production of defect-free billets. This can be accomplished by raising cooling water velocity, increasing mold wall thickness, increasing water back pressure, or roughening the cold face near the meniscus. These measures should also be effective in reducing the frequency of breakouts beneath the mold.

Similar content being viewed by others

Abbreviations

- Cp :

-

Specific heat, J/kg K

- Csf :

-

Empirical constant that depends on the nature of the heating surface/fluid combination

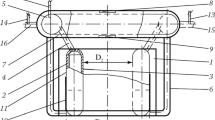

- dw :

-

Water channel gap, width, m

- DH :

-

Hydraulic diameter, m

- g :

-

Gravitational acceleration, m/s2

- ha :

-

Radiant heat-transfer coefficient at the hot face above the meniscus, W/m2 K

- hfc :

-

Forced convection heat-transfer coefficient

- hw :

-

Heat-transfer coefficient at the mold/cooling water interface

- Hfg :

-

Latent heat of vaporization, J/kg

- k :

-

Thermal conductivity, W/mK

- L :

-

Distance from entrance of channel, m

- P :

-

Water pressure, kPa

- Pr :

-

Prandtl number

- qb :

-

Boiling heat flux, W/m2

- qfc :

-

Forced convection heat flux

- qin :

-

Heat flux at point of incipient boiling

- qo :

-

Heat flux from mold to cooling water

- qs :

-

Heat flux from steel to mold

- qir :

-

Heat flux in transition region between forced convection and nucleate boiling

- Re :

-

Reynolds number

- t :

-

Time, s

- T :

-

Mold wall temperature, K

- To :

-

Ambient temperature

- T0 :

-

Initial mold temperature

- Tsat :

-

Saturation temperature of water

- Tw :

-

Water temperature

- Tow :

-

Initial water temperature

- V :

-

Velocity of cooling water in channel, m/s

- x :

-

Transverse spatial coordinate, m

- XM :

-

Thickness of mold wall, m

- z :

-

Longitudinal spatial coordinate, m

- ZF :

-

Height of freeboard in the mold, m

- ZM :

-

Mold length, m

- μ :

-

Viscosity of fluid,N ⋅s/m2

- π :

-

Density of fluid, kg/m3

- σ:

-

Surface tension of liquid/vapor interface,N/m

- f :

-

Fluid

- l :

-

Liquid

- m :

-

Mold

- v:

-

Saturated vapor

- w :

-

Water

References

I.V. Samarasekera and J.K. Brimacombe:Can. Met. Quart., 1979, vol. 18, pp. 251–66.

I. V. Samarasekera, D. L. Anderson, and J. K. Brimacombe:Metall. Trans. B, 1982, vol. 13B, pp. 91–104.

D. I. Brown:Open Hearth Proc, AIME, 1965, vol. 48, pp. 102–10.

J. E. Lait, J. K. Brimacombe, F. Weinberg, and F. C. Muttitt:Open Hearth Proc. AIME, 1973, vol. 56, pp. 269–302.

J. K. Brimacombe, E. B. Hawbolt, and F. Weinberg:Metall. Trans. B, 1979, vol. 10B, pp. 279–92.

Y. Aketa and K. Ushijima:Tetsu-to-Hagané, 1960, vol. 46, pp. 1733–40.

H. G. Baumann and W.J. Löpmann:Wire World Int., 1974, vol. 16, pp. 149–55.

V. P. Perminov, N.M. Lapotyshkin, V. E. Girskii, and A.I. Chizhikov.Stal in English, 1968, vol. 7, pp. 560–63.

H. Mori:Tetsu-to-Hagané, 1972, vol. 58, pp. 1511–25.

W. P. Young and W. T. Whitfield:Open Hearth Proc, AIME, 1968, vol. 51, pp. 127–32.

U.K. Matsunaga:Open Hearth Proc, AIME, 1976, vol. 59, pp. 228–48.

Y. Aketa and K. Ushijima:Tetsu-to-Hagané Overseas, 1962, vol. 2, pp. 334–43.

K. Ushijima:Continuous Casting of Steel, Iron Steel Inst., London, 1964, pp. 59–71.

K. Fujinami: Funabashi Steelworks Ltd., Funabashi, Japan, unpublpublished research, 1977.

J. E. McConnell:Open Hearth Proc, AIME, 1972, vol. 55, pp. 56–72.

Georgetown Texas Steel Corp., private communication.

Jones and Laughlin Steel Corp., private communication.

Chaparral Steel Company, private communication.

Atlantic Steel Company, private communication.

S. N. Singh and K. E. Blazek:Open Hearth Proc AIME, 1976, vol. 59, pp. 264–83.

Handbook of Heat Transfer, W. M. Rohsenow and J. P. Hartnett, eds., McGraw Hill Book Co., 1973, pp. 13-1, 13-75.

W. H. McAdams:Heat Transmission, 3rd ed., McGraw Hill Book Co., New York, NY, 1954, p. 389.

A. E. Bergles and W. M. Rohsenow:J. Heat Transfer, Trans. ASME, Sen C, August 1964, vol. 86, pp. 365–71.

M. Jakob:Heat Transfer, John Wiley and Sons, Inc., New York, NY, 1949, vol. 1, p. 638.

C. Corty and A. S. Foust:Chemical Eng. Progr. Symp. Ser. 51, 1955, vol. 17, pp. 1–12.

B. Carnahan, H.A. Luther, and J.O. Wilkes:Applied Numerical Methods, John Wiley and Sons, Inc., 1969.

S. T. Hsu and F. W. Schmidt:J. Heat Transfer, Trans. ASME, Ser. C, August 1961, vol. 83, pp. 254–60.

R. E. Aseev, V. N. Zhuchin, and V. M. Kondrashin:Steel in the U.S.S.R., April 1972, vol. 2, pp. 284–86.

L.I. Morozenskii, O.A. Mitenev, and V.K. Krutikov:Stal, 1965, no. 4, pp. 272-76.

J.K. Brimacombe, F. Weinberg, and E.B. Hawbolt:Can. Met. Quart., 1980, vol. 19, pp. 215–27.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Samarasekera, I.V., Brimacombe, J.K. The influence of mold behavior on the production of continuously cast steel billets. Metall Trans B 13, 105–116 (1982). https://doi.org/10.1007/BF02666961

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02666961