Abstract

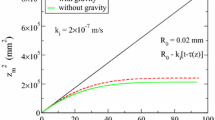

An equation for modeling the kinetics of liquid-metal infiltration into a porous compact has been developed. The model is based on considering a bundle of capillary tubes as an analog for the porous compact. A solution which describes a limiting form of behavior has been shown to be valid for small extents of infiltration relative to a hypothetical static state. The numerical solutions of the dimensionless infiltration-equation have been used to delineate conditions for which limiting solutions are valid. A dimensionless group λ has been shown to be capable of classifying the behavior into two limiting cases: either “inviscid-flow“, λ 10-2, or “viscous-flow“, λ > 102. It would appear that for capillary-tube (pore) radii less than 100 µ-m and for conditions where the compact is wetted by the liquid metal, A is likely to be >100 and therefore correspond to a “viscous-flow system“. Also, an infiltration-rate parameter, ϕ, has been selected which can be used to assess the effects of alloying additions to the liquid-metal infiltrant. This parameter can therefore provide for the selection of alloy infiltrants, surface preparation modification, and processing parameters such as temperature, time of infiltration, and pore size of compact in regard to the processing of composites. Although the model concept (capillary-tube bundle) is recognized as being deficient in not treating the compact as what it really is (a porous medium), the work presented was intended to quantify the limiting behavior of the capillary-tube-bundle approach which has been used in the past.

Similar content being viewed by others

References

I. J. Toth, W. D. Brentnall, and G. D. Menke:J. Metals, 1972, vol. 24, pp. 19–25.

T. W. Clyne and M. G. BadenFifth Intern. Conf. on Comp. Materials: ICCM-V, San Diego, CA, 1985, pp. 755–71.

K.A. Semlak and F. N. Rhines:AIME Trans., 1958, vol. 21, pp. 325–31.

W. E. Brittin:Journ. App. Phys., 1946, vol. 17, pp. 37–44.

J.R. Ligenza and R. B. Bernstein:Journ. Am. Chem. Soc.,1951, vol. 73, pp. 4636–38.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Martins, G.P., Olson, D.L. & Edwards, G.R. Modeling of infiltration kinetics for liquid metal processing of composites. Metall Trans B 19, 95–101 (1988). https://doi.org/10.1007/BF02666495

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02666495