Abstract

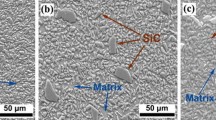

The influence of particle size and volume percent of Mo particles on flake-forming behavior of Mo powders during a ball milling process and three-point flexural strength and fracture toughness of A12O3 composites reinforced with flaky Mo particles have been investigated. The flake-forming behavior of Mo powders mixed with A12O3 powders becomes prominent with increasing Mo particle size, while remaining almost independent of Mo volume percent. The microstructure of the composites reinforced with flaky Mo particles is anisotropic, depending on the arrangement of these Mo particles in the A12O3 matrix. The microdispersion of flaky Mo particles contributes remarkably to an increase in both flexural strength and fracture toughness. The flexural strength increases with decreasing Mo particle size, while the fracture toughness increases with increasing Mo particle size, which corresponds to an increase of the flake-forming tendency of these particles. Furthermore, the flexural strength and fracture toughness can be simultaneously improved by increasing the volume fraction of flaky Mo particles. The microstructural observations indicate that the improvement in strength may be attributed to a grain-refining effect due to inhibition of grain growth of the matrix by the presence of Mo particles. In addition, the improvement in fracture toughness may be due to plastic deformation of Mo particles at a crack tip, which is accelerated more by the flaky rather than the small spherical shape.

Similar content being viewed by others

References

P. F. Becher and G. C. Wei:J. Am. Ceram. Soc., 1984, vol. 67, pp. C-267~C-269.

S. Lio, M. Watanabe, M. Matsubara, and Y. Matsuo:J. Am. Cer. Soc., 1989, vol. 72, pp. 1880–84.

N. Tamari, T. Tanaka, I. Kondoh, and S. Kose:J. Cer. Soc. Jpn., 1991, vol. 99, pp. 370–75.

S. Kanzaki:Nikkei Mater. Technol., 1994, vol. 5, pp. 62–66.

M. Nawa, T. Sekino, and K. Niihara:J. Jpn. Soc. Powder Powder Metall., 1992, vol. 39, pp. 1104–08.

K. Niihara, A. Nakahira, T. Uchiyama, and T. Hirai: inFracture Mechanics of Ceramics, R. C. Bradt, A. G. Evans, D. P. H. Hasselman, and F. F. Lange, eds., Plenum Press, New York, NY, 1986, pp. 103–16.

Y. Waku, M. Suzuki, Y. Oda, and Y. Kohtoku:J. Cer. Soc. Jpn., 1995, vol. 103, pp. 713–19.

H. Awaji and Y. Sakaido:J. Am. Cer. Soc., 1990, vol. 73, pp. 3522–23.

R. L. Fullman:Trans. AIME, 1953, vol. 197, pp. 447–52.

M. Nawa, T. Sekino, and K. Niihara:J. Mater. Sci., 1994, vol. 29, pp. 3185–92.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Waku, Y., Suzuki, M., Oda, Y. et al. Influence of particle size and volume percent of flaky mo particles on the mechanical properties of AI2O3/Mo composites. Metall Mater Trans A 27, 3307–3317 (1996). https://doi.org/10.1007/BF02663880

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02663880