Abstract

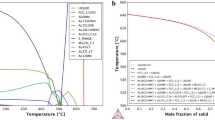

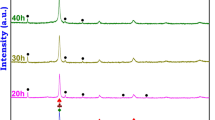

The rod milling technique using the mechanical alloying (MA) process has been employed for preparing amorphous Al33Ta67 alloy starting from elemental Al and Ta powders. X-ray diffraction (XRD), differential thermal analysis (DTA), differential scanning calorimetry (DSC), optical microscopy, scanning electron microscopy (SEM), and transmission electron microscopy (TEM) are utilized to follow the progress of amorphization. The results show that during the first few kiloseconds of MA time, layered composite particles of Al and Ta are intermixed and form an amorphous phase upon heating to 685 K by DTA. This process is called thermally assisted solid-state amorphization (TASSA). During the early stage of milling, the number of layers of the composite particles increases. This leads to an increase in the heat formation of amorphous Al33Ta67 alloyvia the TASSA process, ΔH aTASSA . After 360 ks (100 h) of the MA time, all Al atoms emigrate to Ta lattices to form a solid solution phase and the powder particles have no more layered structure. At this stage of milling, the value of ΔH aTASSA becomes zero. This solid solution phase is not stable against the shear forces that are generated by the rods and transforms completely to an amorphous phase upon milling for 720 ks (200 hours). This phase transformation is attributed to the accumulation of several lattice imperfections, such as point and lattice defects, which raise the free energy from the more stable phase (solid solution) to a less stable phase (amorphous). After 1440 ks (400 hours) of MA time, a homogeneous amorphous phase is formed. The amorphization process in this case is attributed to a mechanical driven solid-state amorphization (MDSSA). The heat of formation of the amorphous phase formedvia the MDSSA process, ΔH aMDSSA , has been calculated. Moreover, the crystallization characteristics indexed by the crystallization temperature, and the enthalphy of crystallization, of the amorphous phases formed by TASSA and MDSSA processes are investigated as a function of MA time. The role of amorphizationvia each process has been discussed.

Similar content being viewed by others

References

J.S. Benjamin:Metall. Trans., 1970, vol. 1, pp. 2943–51.

I.G. Wright and A. Wilox:Metall. Trans., 1974, vol. 5, pp. 957–60.

G.H. Gessinger:Metall. Trans. A, 1976, vol. 7A, pp. 1203–09.

J.S. Benjamin:Sci. Am., 1976, vol. 40, pp. 234–40.

J.S. Benjamin and M.J. Bomford:Metall. Trans. A, 1977, vol. 8A, pp. 1301–05.

P.S. Gilman and W.D. Nix:Metall. Trans. A, 1981, vol. 12A, pp. 813–24.

C.C. Koch, O.B. Cavin, C.G. MacKamey, and J.O. Scarbourgh:Appl. Phys. Lett., 1983, vol. 43, pp. 1017–19.

M. Sherif El-Eskandarany, K. Aoki, and K. Suzuki:J. Less-Common Met, 1990, vol. 167, pp. 113–18.

C. Politis and W.L. Johnson:J. Appl. Phys., 1986, vol. 60, pp. 1147–51.

R. Schwarz and C.C. Koch:Appl. Phys. Lett, 1986, vol. 49, pp. 146–49.

M. Sherif El-Eskandarany, K. Aoki, and K. Suzuki:J. Appl. Phys., 1992, vol. 72, pp. 2665–72.

M. Sherif El-Eskandarany, K. Aoki, and K. Suzuki:Metall. Trans. A, 1992, vol. 23A, pp. 2131–40.

M. Sherif El-Eskandarany, K. Aoki, and K. Suzuki:J. Appl. Phys., 1992, vol. 71, pp. 2924–30.

M. Sherif El-Eskandarany, K. Aoki, and K. Suzuki:Appl. Phys. Lett, 1992, vol. 60, pp. 1562–63.

M. Sherif El-Eskandarany:J. Alloys Comp., 1996, vol. 234 (1), p. 67.

M. Sherif El-Eskandarany, K. Aoki, and K. Suzuki:Scripta Metall, 1991, vol. 25, pp. 1695–1700.

M. Sherif El-Eskandarany, K. Aoki, T. Masumoto, and K. Suzuki:J. Alloys Comp., 1994, vol. 209, pp. 71–79.

H.E. Kissinger:Analyt. Chem., 1957, vol. 29, pp. 1702–06.

F.R. de Boer, R. Boom, W.C.M. Mattens, A.R. Miedema, and A.K. Niessen:Cohesion in Metals-Transition Metal Alloys, 1st ed., North-Holland, Amsterdam, 1988, vol. 1, p. 545.

R.B. Schwarz and R.R. Petrich:J. Less-Common Met., 1988, vol. 140, pp. 171–84.

M. Van Rossum, M.-A. Nicolet, and W.L. Johnson:Phys. Rev. B, 1984, vol. 29, pp. 5498–5503.

E.J. Cotts, G.C. Wong, and W.L. Johnson:Phys. Rev. B, 1988, vol. 37, pp. 9049–52.

Author information

Authors and Affiliations

Additional information

Formerly lecturer of Materials Science, Department of Mining and Petroleum Engineering, Faculty of Engineering, AI-Azhar University, Nasr City 11884, Cairo, Egypt

Rights and permissions

About this article

Cite this article

El-Eskandarany, M.S. Thermally assisted and mechanically driven solid-state reactions for formation of amorphous AI33Ta67 alloy powders. Metall Mater Trans A 27, 3267–3278 (1996). https://doi.org/10.1007/BF02663877

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02663877