Abstract

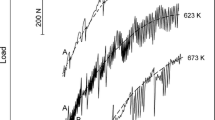

The strengthening mechanisms in the cobalt alloy MP35N have been investigated by tensile and creep deformation at elevated temperatures and by transmission electron microscopy (TEM) of the deformed alloy. A high ultimate tensile strength (UTS) of 800 to 900 MPa was maintained at all test temperatures from 300 to 873 K due to the maintenance of high strain hardening. On straining, there was the usual initial fall of the strain-hardening rate with stress, but above a critical stress of about 500 MPa, the strain-hardening rate stopped falling and was held almost constant at about 2000 MPa. At 973 and 1073 K, this high strain-hardening rate suddenly ceased during the test, while at 1123 K, negligible strain hardening was seen. At temperatures between 673 and 1073 K, tensile load drops were seen whose magnitude increased with strain, and thus stress, at a fixed temperature. The load drops also increased with increased temperature. How-ever, in conditions when the strain-hardening rate fell to a low value, the load drops ceased. In a tensile test in which small increments of strain were applied as the temperature was increased in 10 K intervals, a steadily rising flow stress with temperature was seen up to a critical temperature of 1073 K, beyond which the flow stress fell and the load drops also ceased. In conditions where the high rate of strain hardening was found, fine platelike structures were seen by transmission electron microscopy (TEM) to form on {111} planes in the face-centered cubic (fcc) matrix. Diffraction evidence showed that these were faulted hexagonal close-packed (hep) plates. Creep tests carried out above and below the critical temperature of 1073 K showed very different behavior. At 1098 K, the sample showed conventional creep behavior, while at a temperature of 973 K, the material showed sigmoidal creep strain rate. At low strains, up to a strain of about 0.02, there was an initial steady-state creep rate. The creep strain rate then increased and fell back to a second steady-state creep rate. During the accelerated creep stage, hexagonal plates were again seen to form. Strain-induced martensite forming at temperatures up to and including 1073 K, but not at higher temperatures, appears to account satisfactorily for all of the behavior seen in this study. It is proposed that the hexagonal plates form martensitically at high speed, but as proposed in Part I,[1] solute partitioning occurs between the closely spaced fcc and hcp phases. At 1025 and 1073 K, the end of both the load drops and the high strain hardening during a tensile test may be explained by the stabilization of the remaining fcc matrix by loss of hexagonal phase stabilizing solute. The critical temperature of approximately 1073 K seen in this study is close to the critical softening temperature of 1083 K, above which recrystallization of cold-worked MP35N occurs readily (Part I[1])- The critical temperature is proposed to be close to the transus temperature, above which single-phase fcc is the stable structure of MP35N.

Similar content being viewed by others

References

R.P. Singh and R.D. Doherty:Metall. Trans. A, 1992, vol. 23A, pp. 307–19.

H. Mecking and U.F. Kocks:Acta Metall., 1981, vol. 29, pp. 1865–75.

U.F. Kocks, A.S. Argon, and M.F. Ashby:Prog. Mater. Sci., 1980, vol. 19, pp. 1–288.

R.A. Mulford and U.F. Kocks:Acta Metall., 1979, vol. 27, pp. 1125–34.

R.P. Singh: Ph.D. Thesis, Drexel University, Philadelphia, PA, 1987.

R.H. Richman and G.F. Boiling:Acta Metall., 1970, vol. 18, pp. 673–81.

R.H. Richman and G.F. Boiling:Metall. Trans., 1971, vol. 2, pp. 2451–62.

H.J. Kestanbach:Metallography, 1977, vol. 10, pp. 189–99.

M.W. Bowkett, S.R. Keown, and D.R. Harries:Met. Sci., 1982, vol. 16, pp. 499–517.

L. Remy:Metall. Trans. A, 1977, vol. 8A, pp. 253–58.

Y.N. Dastur and W.L. Leslie: inStrength of Metals and Alloys, P. Haasen, V. Gerold, and G. Kostorz, eds., Pergamon Press, New York, NY, 1979, pp. 619-22.

L. Remy and A. Pineau:Mater. Sci. Eng., 1978, vol. 36, pp. 47–63.

L. Brewer and D.G. Davis:Metall. Trans. A, 1984, vol. 15A, pp. 67–72.

M. Hansen and K. Anderko:Constitution of Binary Alloys, McGraw-Hill, New York, NY, 1958.

M. Raghavan, B.J. Berkowitz, and R.D. Kane:Metall. Trans. A., 1980, vol. 11 A, pp. 203–07.

A.H. Cottrell:Dislocations and Plastic Flow in Crystals, Clarendon, Oxford, United Kingdom, 1953.

B.J. Brindley and P.J. Worthington:Int. Met. Rev., 1970, vol. 15, pp. 101–14.

J.D. Bird:Int. Met. Rev., 1971, vol. 16, pp. 1–18.

I.S. Kim and M.C. Chaturvedi:Met. Sci., 1979, pp. 691-95.

A.K. Koul and F.B. Pickering:Scripta Metall., 1982, vol. 16, pp. 119–24.

A. van den Beukel and U.F. Kocks:Acta Metall., 1982, vol. 30, pp. 1027–34.

P. Wycliffe, U.F. Kocks, and J.D. Embury:Scripta Metall., 1980, vol. 14, pp. 1349–54.

P.G. McCormick:Acta Metall., 1972, vol. 20, pp. 351–54.

A. van den Beukel:Phys. Status Solidi A, 1975, vol. 30, pp. 197–206.

L.J. Cuddy and W.L. Leslie:Acta Metall., 1972, vol. 20, pp. 1157–67.

L.H. Almeida, I.L. May, and S.N. Monteiro:Scripta Metall., 1985, vol. 14, pp. 1451–54.

E. Pink and A. Grinberg:Acta Metall., 1982, vol. 30, pp. 2153–60.

N. Narita and J. Takamura:Phil. Mag., 1974, vol. 17, pp. 1001–28.

S. Mahajan and D.F. Williams:Int. Met. Rev., 1973, vol. 18, pp. 43–61.

J.A. Venables: inDeformation Twinning, R.E. Reed-Hill, J.P. Hirth, and H.C. Rogers, eds., Gorden and Breach Science Publishers, New York, NY, 1964, pp. 77-116.

J.A. Venables:J. Phys. Chem. Solids, 1964, vol. 25, pp. 685–92.

J.A. Venables:J. Phys. Chem. Solids, 1964, vol. 25, pp. 693–700.

Z. Nishiyahama:Martensitic Transformations, Academic Press, New York, NY, 1978.

C.M. Wayman: inPhysical Metallurgy, R.W. Cahn and P. Haseen, eds., Elsevier Science Publishers, Amsterdam, The Netherlands, 1983, pp. 1031-74.

E. Sato, E. Chishima, Y. Yamaji, and T. Mori:Acta Metall., 1984, vol. 32, pp. 539–47.

O.D. Sherby and P.M. Burke:Prog. Mater. Sci., 1967, vol. 13, pp. 325–90.

S. Takeuchi and A.S. Argon:J. Mater. Sci., 1976, vol. 11, pp. 1542–66.

A.K. Mukherjee: inTreatise on Materials Science and Technology: Plastic Deformation of Materials, Vol. 6, R.J. Arsenault, ed., Academic Press, New York, NY, 1975, pp. 163-224.

R.W. Evan and B. Wilsire:Creep of Metals and Alloys, The Institute of Metals, London, 1985.

R.P. Singh and R.D. Doherty: Drexel University, Philadelphia, PA, unpublished research, 1991.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Singh, R.p., Doherty, R.D. Strengthening in MULTIPHASE(MP35N) alloy: Part II. elevated temperature tensile and creep deformation. Metall Trans A 23, 321–334 (1992). https://doi.org/10.1007/BF02660874

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02660874