Abstract

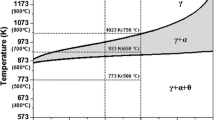

In Fe-4 pct Mo-0.2 pct C martensite which is a typical secondary hardening steel, premature failure occurred in tensile test at 600 °C to 700 °C where solute atoms could diffuse easily. To clarify this phenomenon, the quenched specimens were tempered under applied stress and tensile-tested at room temperature. The following results were obtained: (1) Typical intergranular fracture was observed in specimens tempered in a temperature range of 600 °C to 650 °C with tempering times of five minutes to 10 minutes and applied stress (70 MPa to 140 MPa). (2) Based on Auger analysis, this phenomenon was considered to be caused by segregation of P, S, and Mo on prior austenite grain boundaries due to applied stress. (3) The direction of applied stress was found to be very significant. Namely, when the tensile direction was parallel to the applied stress during tempering, the specimen was more brittle, and when tensile direction was normal to the applied stress, the specimen was not so brittle. (4) To reduce this embrittlement, solution treatment temperature was adjusted, and it was found that the embrittlement was considerably reduced both in specimens with fine prior austenite grains and with some ferrite phase on prior austenite grain boundaries.

Similar content being viewed by others

References

E. R. N. Nabarro: “Report on Strength of Solid”, Phys. Soc., London, 1948.

A.H. Cottrell:Phil. Mag., 1953, vol. 44, p. 829.

J. Friedel: “Dislocation”, Pergamon Press, London, 1964.

S. Miura, J. Takamura, and M. Yamashita:Suiyokwai-shi (Japan), 1967, vol. 16, p. 395.

H. Yoshinaga and S. Morozumi:Phil. Mag., 1971, vol. 23, p. 1351.

A. Korbel, J. Zasadzinslci, and Z. Sieklucka:Acta Met., 1976, vol. 24, p. 919.

G. R. Purdy:Acta Met., 1978, vol. 26, p. 487.

E. W. Page, P. Manganon Jr., G. Thomas, and V. F. Zackey:Trans. ASM, 1969, vol. 62, p. 45.

Y. Nakada, W. C. Leslie, and T. P. Churay:Trans. ASM, 1967, vol. 60, p. 223.

Y. Tanaka, A. Sato, and T. Mori:Acta Met., 1978, vol. 26, p. 529.

E. J. Hall:JISI, 1952, vol. 170, p. 331.

B. J. Brindley:Acta Met., 1970, vol. 18, p. 325.

I. Tamura, M. Tokizane, and Y. Ashida:Trans. 1SIJ, 1970, vol. 10, p. 188.

Y. Ito and M. Nakanishi:J.Jpn. Welding Soc., 1971, vol. 40, p. 1261.

Y. Ito and M. Nakanishi:J. Jpn. Welding Soc., 1972, vol. 41, p. 59.

H. Ikawa, Y. Nakano, T. Kikuchi, and H. Takehara:J. Jpn. Welding Soc., 1978, vol. 47, p. 425.

J. J. Irani and R.W. K. Honeycombe:JISI, 1965, vol. 203, p. 826.

D. Raynor, J. A. Whiteman, and R. W. K. Honeycombe:JISI, 1966, vol. 204, p. 349.

I. Tamura, T. Maki, and S. Fujiwara:Suppl. Trans. Jpn. Inst. Metals, 1968, vol. 9, p. 412.

I. Tamura, S. Fujiwara, H. Nakata, and J. Kawai:Proc. ICSTIS, Trans. Iron Steel Inst. Jpn., 1971, vol. 11, p. 1184.

S. Fujiwara, H. Nakata, and I. Tamura:J. Jpn. Inst. Metals, 1972, vol. 36, p. 46.

A. E. Powers:JISI, 1957, vol. 186, p. 323.

J. W. Capus:Metallurgie, 1960, vol. 62, p. 133.

H. L. Marcus and P. W. Palmberg:Trans. TMS-AIME, 1969, vol. 245, p. 1664.

M. Braunovic and C.W. Harworth:Met. Sci., 1970, vol. 4, p. 85.

T. Swarr and G. Krauss:Metall. Trans. A, 1976, vol. 7A, p. 41.

G. Krauss: “Mechanical Behavior of Metals and Alloys Associated with Displacive Phase Transformations”,Proc, A Joint U.S./Japan Seminar, 1979, p. 138.

A. P. Tabor, J. F. Thorlin, and J. F. Wallance:Trans. ASM, 1950, vol. 42, p. 1033.

M. Baeyertz, W. F. Craig, and J. P. Sheeham:Trans. AIME, 1950, vol. 188, p. 389.

H. Suto and S. Yamanouchi:J. Jpn. Inst. Metals, 1978, vol. 42, p. 1122.

R. D. Kane and W. K. Boyd: “Alloys for the Eighties”, Climax Molybdenum Company, Ann Arbor, MI, 1980, p. 225.

H. Ohotani, H. C. Feng, C. J. McMahon, and R. A. Mulford:Metall. Trans. A, 1976, vol. 7A, p. 87.

M. Mclean and E. D. Hondros:J. Mater. Sci., 1973, vol. 8, p. 349.

M. Guttmann:Met. Sci., 1976, vol. 10, p. 337.

M.P. Seah:Acta Met., 1977, vol. 25, p. 345.

R. G. C. Hill:Metal Treatment, 1962, vol. 29, p. 301.

E. D. Hondros and M. P. Seah:Int. Met. Rev., 1977, vol. 222, p. 262.

I. Tamura and S. Fujiwara: “High Strength Martensitic Steels,” Proc. International Symposium CSVTS, 1975, p. 253.

K. Kuo:JISI, 1953, vol. 173, p. 363.

A. K. Seal and R. W. K. Honeycombe:JISI, 1958, vol. 188, p. 343.

K.J. Irvine and F. B. Pickering:JISJ, 1960, vol. 194, p. 137.

D.J. Dyson and K.W. Andrews:JISI, 1964, vol. 202, p. 325.

K. Narita:Bulletin Jpn. Inst. Metals, 1968, vol. 7, p. 742.

B.C. Woodfine:JISI, 1953, vol. 173, p. 229.

J.W. Capus:JISI, 1962, vol. 200, p. 922.

C. Herring:J. Appl. Phys., 1950, vol. 21, p. 437.

S. Kihara, J. Newkirk, A. Ohtomo, and Y. Saiga:Metall. Trans. A, 1980, vol. 11A, p. 1019.

C.J. McMahon, E. Furubayashi, H. Ohtani, and H. C. Feng:Acta Met., 1976, vol. 24, p. 695.

R. A. Mulford, C. J. McMahon, D. P. Pope, and H. C. Feng:Metall. Trans. A, 1976, vol. 7A, p. 1183.

K.J. DeVos:Z. Angew. Phys., 1964, vol. 17, p. 168.

S.D. Dahlgren:Metall. Trans. A, 1977, vol. 8A, p. 347.

J.D. Murray:British Welding J., 1967, vol. 14, p. 447.

D. Webster:Trans. ASM, 1969, vol. 62, p. 759.

T. Yasunaka and T. Araki:J. Jpn. Inst. Metals, 1972, vol. 36, p. 1202.

Author information

Authors and Affiliations

Additional information

Formerly with Kyoto University

Formerly with Kyoto University

This paper is based on a presentation made at the “Peter G. Winchell Symposium on Tempering of Steel” held at the Louisville Meeting of The Metallurgical Society of AIME, October 12-13, 1981, under the sponsorship of the TMS-AIME Ferrous Metallurgy and Heat Treatment Committees.

Rights and permissions

About this article

Cite this article

Fujiwara, S., Ogawa, T., Ohmura, Y. et al. The Tensile Properties of an Fe-4 Pct Mo-0.2 Pct C Martensite Tempered under Applied Stress. Metall Trans A 14, 1067–1077 (1983). https://doi.org/10.1007/BF02659855

Issue Date:

DOI: https://doi.org/10.1007/BF02659855