Abstract

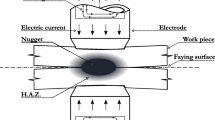

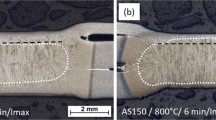

Material variations and process modifications have been studied to determine their effects on the acceptable range of resistance spot welding conditions for galvanized steel sheet. The material variations studied include zinc coating integrity, structure, composition, thickness, roughness, oil, and the amount and type of Fe-Zn intermetallics. Process modifications studied include upsloping and downsloping of the weld current, preheat current, postheat current, electrode tip geometry, and applied force. It was found that hot-dipped galvanized materials with coatings which have a very thin Fe-Zn alloy layer have a wider range of acceptable welding conditions than the commercial galvannealed products, which have a fully alloyed Fe-Zn coating. The decreased lobe width of the galvannealed material is due to the discontinuous Fe-Zn coating structure and morphology. Small variations in the thickness of the coatings studied have no significant effect on the welding current range. Surface roughness of the coating has no effect on lobe width. Upsloping and downsloping of the weld current increase the welding range of hot-dipped products when using truncated cone electrodes, whereas sloped current has no advantage for galvannealed or uncoated materials. Radiused electrodes can increase the lobe width of hot-dipped products but are not beneficial when using sloped current or when welding galvannealed or uncoated materials.

Similar content being viewed by others

References

D.W. Dickinson and T.V. Natale:Trans. ASM/ADDRG, 1981.

R.C. Lavery and N.T. Williams:Sheet Met. Ind., 1970, vol. 43, pp. 201–04, 209–10, 224.

L. M. Friedman: Master’s Thesis, The Ohio State University, Columbus, OH, 1965.

H. J. Krause and G. Simon:Proc. Conf. on Resistance Welding, Essen, Sept. 1981, pp. 85-100.

K. I. Johnson: Welding Institute Research Report, P/74/75, 1975.

L. D. Connel:Met. Constr., 1970, vol. 2, pp. 68–72.

A.V. Nadhorni and E. P. Weber:Welding J., 1977, vol. 56, pp. 331s-38s.

“Recommended Practices for Resistance Welding Coated Low Carbon Steels”, AWS CL. 3–70, American Welding Society, 1970.

B. Pollard:Welding J., 1974, pp. 343s-50s.

S. A. Gedeon, D. Schrock, J. LaPointe, and T. W. Eagar. SAE Technical Paper 840113, 1984.

H. J. Krause and G. Simon: IIW Doc. III-716-82, 1982.

S. Mathiev and P. Patou: SAE Technical Paper 850273, 1985.

R. V. Fostini and W. Dilay: Trans. ASM/ADDRG Conf., 1981.

L. M. Friedman and R. B. McCauley:Welding J., 1969, vol. 48, pp. 454s-62s.

J. Mackowiak and N. R. Short:Int. Met. Rev., 1979, vol. 24, pp. 1–17.

M. J. Graham, P. E. Beaubien, and G. I. Sproule:J. Mater. Sci., 1980, vol. 15, pp. 626–30.

H. Smith and W. Batz:J. Iron Steel Inst., 1972, vol. 210, pp. 895–900.

W.F. Savage, E.F. Nippes, and F.A. Wassel:Welding J., 1977, vol. 56, pp. 365s-70s.

W.F. Savage, E.F. Nippes, and F.A. Wassel:Welding J., 1978, vol. 57, pp. 43s-50s.

J. G. Kaiser, G. J. Dunn, and T. W. Eagar:Welding J., 1982, vol. 61, pp. 167s-74s.

D. Watney: development engineer, General Motors Corporation, Warren, MI 48090-9040, 1984, unpublished research.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Gedeon, S.A., Eagar, T.W. Resistance spot welding of galvanized steel: Part I. Material variations and process modifications. Metall Trans B 17, 879–885 (1986). https://doi.org/10.1007/BF02657151

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02657151