Abstract

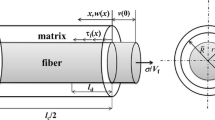

A trial to predict the influences of ductility of matrix, interfacial bonding strength, and volume fraction of fiber on the tensile strength of unidirectional metal matrix composites was attempted by means of a Monte Carlo computer simulation method. The main results are summarized as follows. (1) The strength of strongly bonded composites increased with increasing ductility of matrix and then remained nearly constant. (2) When the matrix was ductile, the strength of composite increased with increasing interfacial bonding strength and then remained nearly constant. When the matrix was not ductile, the strength increased but then decreased with interfacial bonding strength. In this case, there was an optimum bonding strength, for which the strength of composite was highest. (3) Concerning the strength of composite as a function of volume fraction of fiber, there arose the case where it is approximately described by the rule of mixtures and also the case where it is not described by this rule, depending on the ductility of matrix, interfacial bonding strength, and scatter of strength of fiber.

Similar content being viewed by others

References

B.W. Rosen:AIAA J., 1964, vol. 2, pp. 1985–91.

C. Zweben:AIAA J., 1968, vol. 6, pp. 2325–31.

C. Zweben and B.W. Rosen:J. Mech. Phys. Solids, 1970, vol. 18, pp. 189–206.

S. Ochiai, K. Osamura, and K. Abe:Z. Metallkd., 1985, vol. 76, pp. 402–08.

S. Ochiai and K. Osamura:Z. Metallkd., 1985, vol. 76, pp. 485–91.

S. Ochiai and K. Osamura:J. Mater. Sei., 1988, vol. 23, pp. 886–93.

S. Ochiai and K. Osamura:Metall. Trans. A, 1988, vol. 19A, pp. 1491–97.

S. Ochiai and K. Osamura: inEngineering Applications of New Composites, S.A. Paipetis and G.C. Papanicolau, eds., Omega Scientific, Oxon, England, 1988, pp. 492–98.

S. Ochiai and K. Osamura: inInterfaces in Polymer, Ceramics, and Metal Matrix Composites, H. Ishida, ed., Elsevier Science Publishing Company, Inc., New York, NY, 1988, pp. 413–23.

G.A. Cooper and A. Kelly:J. Mech. Phys., 1967, vol. 15, pp. 279–97.

A.S. Tetelman:Composite Materials: Testing and Design, ASTM STP 460, ASTM, Philadelphia, PA, 1969, pp. 473–502.

S. Ochiai and K. Osamura:Z. Metallkd., 1986, vol.77, pp. 249–54.

W. Weibull:J. Appl. Mech., 1951, vol. 18, pp. 293–96.

C. Zweben:Eng. Fract. Mech., 1974, vol. 6, pp. 1–10.

S. Ochiai, K. Abe, and K. Osamura:Z. Metallkd., 1985, vol. 76, pp. 299–306.

D.L. McDanels, R.W. Jech, and J.W. Weeton:Trans. TMS-AIME, 1965, vol. 233, pp. 636–42.

A. Kelly and W.R. Tyson:J. Mech. Phys. Solids, 1965, vol. 13, pp. 329–50.

A. Kohara and N. Muto:Recent Advances in Composites in the United States and Japan, ASTM STP 864, ASTM, Philadelphia, PA, 1985, pp. 456–64.

E. Nakata, Y. Kagawa, H. Miyashita, and H. Noda:Waseda-Daigaku-Chuukennhoukoku, 1981, no. 36, pp. 93–98.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Ochiai, S., Osamura, K. Influences of matrix ductility, interfacial bonding strength, and fiber volume fraction on tensile strength of unidirectional metal matrix composite. Metall Trans A 21, 971–977 (1990). https://doi.org/10.1007/BF02656581

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02656581