Abstract

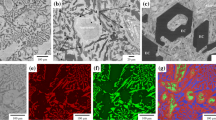

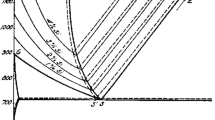

Chromium white cast irons are widely used in environments where severe abrasion resistance is a dominant requirement. To improve the wear resistance of these commercially important irons, the United States Bureau of Mines and CSIRO Australia are studying their solidification and solid-state transformation kinetics. A ternary Fe-Cr-C iron with 17.8 wt pct (pct) Cr and 3.0 pct C was compared with commercially available irons of similar Cr and C contents with Si contents between 1.6 and 2.2 pct. The irons were solidified and cooled at rates of 0.03 and 0.17 K · s-1 to 873 K. Differential thermal analysis (DTA) showed that Si depresses the eutectic reaction temperature and suggests that is has no effect upon the volume of eutectic carbides formed during solidification. Microprobe analysis revealed that austenite dendrites within the Si alloyed irons cooled at 0.03 and 0.17 K·s-1 had C and Cr contents that were lower than those of dendrites within the ternary alloy cooled at the same cooling rate and a Si alloyed iron that was water quenched from the eutectic temperature. These lower values were shown by image analysis to be the result of both solid-state growth (coarsening) of the eutectic carbides and some secondary carbide formation. Hardness measurements in the as-cast condition and after soaking in liquid nitrogen suggest an increase in the martensite start temperature as the Si content was increased. It is concluded that Si’s effect on increasing the size and volume fraction of eutectic carbides and increasing the matrix hardness should lead to improved wear resistance over regular high-chromium white cast irons.

Similar content being viewed by others

References

D.E. Diesburg and F. Borik:Symp. Materials for the Mining Industry, R.Q. Barr, ed., Climax Molybdenum, Vail, CO, 1974, pp. 15–41.

R. Blickensderfer, J.H. Tylczak, and G. Laird II:Wear of Materials, K.C. Ludema, ed., 1989, vol. 1, pp. 175-82.

G. Laird:Trans. Am. Foundry men’s Soc., 1988, vol. 96, pp. 799–806.

P.J. Provias:Can. Min. Metall. Bull., 1965, vol. 58 (641), pp. 923–30.

J.L. Parks:Trans. Am. Foundrymen’s Soc., 1978, vol. 86, pp. 97–102.

Z. Glowacki, J. Baer, and D. Senczyk:Hutnik, 1965, vol. 32, pp. 399–404.

V.G. Rivlin:Int. Met. Rev., 1984, vol. 29, pp. 299–328.

G. Laird, R.R. Brown, and R.L. Nielsen:Mater. Sci. Technol., 1991, vol. 7, pp. 631–42.

G.L.F. Powell:Met. Forum, 1980, vol. 3, pp. 37–46.

Y. Matsubara, K. Ogi, and K. Matsuda:Trans. Am. Foundrymen’s Soc., 1981, vol. 89, pp. 183–96.

K. Ogi, Y. Matsubara, and K. Matsuda:Trans. Am. Foundrymen’s Soc., 1981, vol. 89, pp. 197–204.

F. Maratray and R. Usseglio-Nanot:Atlas of Transformation Characteristics of Cr and Cr-Mo White Irons, 1971, Climax Molybdenum S.A., Paris, France.

G. Laird II:Trans. Am. Foundrymen’s Soc., 1991, vol. 99, pp. 339–57.

G.L.F. Powell and G. Laird II:J. Mater. Sci., 1992, vol. 27, pp. 29–35.

J.T.H. Pearce:Trans. Am. Foundrymen’s Soc., 1984, vol. 92, pp. 599–622.

J. Dodd and J.L. Parks:AFS Int. Cast Metals J., 1980, vol. 5, pp. 47–54.

E.C. Bain, R.H. Aborn, and J.H.B. Rutherford:Trans. Am. Soc. Steel Treating, 1933, vol. 21, pp. 481–509.

T.E. Norman: U.S. Patent No. 4,547,221, 1985.

Mats Waldenström:Metall. Trans. A, 1977, vol. 8A, pp. 1963–77.

R.W. Heine and P.C. Rosenthal:Principles of Metal Casting, McGraw-Hill, New York, NY, 1955, p. 520.

R.W. Heine:AFS Cast Met. Res. J., 1971, vol. 7, pp. 49–54.

J.F. Janowak and R.B. Gundlach:Trans. Am. Foundrymen’s Soc., 1982, vol. 90, pp. 847–63.

A.A. Zhukov:Met. Sci., 1978, vol. 12, pp. 521–24.

Robert Benz, John F. Elliott, and John Chipman:Metall. Trans., 1974, vol. 5, pp. 2235–40.

J. Shen and Q.D. Zhou:Cast Metals, 1988, vol. 1, pp. 79–85.

C. Kim:J. Heat Treating, 1979, vol. 1, pp. 45–51.

C.Y. Kung and J.J. Rayment:Metall. Trans. A, 1982, vol. 13A, pp. 328–31.

K.W. Andrews:J. Iron Steel Inst., 1965, vol. 203, p. 721–27.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Laird, G., Powell, G.L.F. Solidification and solid-state transformation mechanisms in Si alloyed high-chromium white cast irons. Metall Trans A 24, 981–988 (1993). https://doi.org/10.1007/BF02656520

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02656520