Abstract

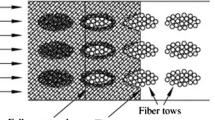

A model for variable pressure infiltration of fibrous preforms by molten metal has been developed. The mechanism of the infiltration and the effects of fiber distribution and wettability on infiltration resistance and composite microstructure have been studied. It is shown that the model is in good agreement with the experimental data on infiltration of carbon-fiber preforms by Al-Si eutectic. The solution of the resulting equation shows that the rate of infiltration is only a function of the rate of change of pressure Ф, by which the infiltration processing is controlled precisely. Two kinds of infiltration modes have been found. A critical fiber volume fractionV c exists, which is the turning point of the infiltration modes as well as permeability. As fiber volume fraction exceedsV c, the infiltration mode changes from nonuniform to uniform, resulting in a sharp decrease in permeability. The permeability and resistances of these two infiltration modes are well predicted by the variable pressure infiltration theory. If fibers are wetted by molten metal, the preforms can be completely infiltrated at low applied pressure. In the case of nonwetting, poor infiltration of the preforms up toV cresults, though high pressure is applied, but quality composites are formed at a low applied pressure if the fibers in the bundles are fixed relative to each other. A novel process, variable pressure infiltration technique, has been generated, which offers the advantages of low applied pressure, easy control of the pro-cessing, and no requirement of wetting. Quality C/A356 composites have been fabricated by this technique with the investment precision casting molds at a pressure of 0.6 MPa. Also, the mechanical properties of the composites are studied. The composites have high strength with a special fracture mechanism.

Similar content being viewed by others

References

G.P. Martins, D.L. Olson, and G.R. Edwards:Metall. Trans. B, 1988, vol. 19B, pp. 95–101.

A. Mortensen, J.A. Cornie, and M.C. Flemings:J. Met., 1988, vol. 40, pp. 12–19.

T.W. Clyne:6th Int. Conf. on Composite Materials, ICCM-VI, London, Elsevier Applied Science, London, 1987, pp. 2.275–286.

A.R. Champion, W.H. Krurger, A.S. Hartam, and A.K. Dhingra:ICCM-II, TMS-AIME, Warrendale, PA, 1978, pp. 883–904.

H. Fukunaga and K. Goda:Bull. JSME, 1984, vol. 27 (228), p. 1245.

L.J. Masur, A. Mortensen, J.A. Cornie, and M.C. Flemings:ICCM-VI, London, 1987, pp. 2.320-329.

A. Mortensen and V. Michaud:Metall. Trans. A, 1990, vol. 21A, pp. 2059–72.

A. Mortensen, L.J. Masur, J.A. Cornie, and M.C. Flemings:Metall. Trans. A, 1989, vol. 20A, pp. 2535–47.

T.W. Clyne and M.G. Bader:ICCM-V, San Diego, CA, TMS- AIME, Warrendale, PA, 1985, pp. 755–62.

J. Bear:Dynamics of Fluids in Porous Media, McGraw-Hill, Inc., New York, NY, 1972, pp. 284–85.

A.P. Majidi, J.M. Yang, and T.W. Chou:Interfaces in Metal- Matrix Composites, Proc. Conf., New Orleans, AIME, 1986, pp. 27-44.

Z.H. Xia:3rd Youth Conf. on Materials Science, Dalian, People's Republic of China, C-MRS, Beijing, 1991, pp. 2.385–388.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Xia, Z., Zhou, Y., Mao, Z. et al. Fabrication of fiber-reinforced metal-matrix composites by variable pressure infiltration. Metall Trans B 23, 295–302 (1992). https://doi.org/10.1007/BF02656284

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF02656284