Abstract

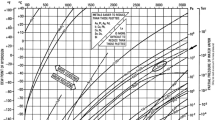

The settling of 14-μm silicon carbide particles in an aluminum-silicon alloy was monitored with an electrical resistance probe to measure thein situ particle voluem fraction. The rate of settling was much greater than expected from hindered settling of single 14-μm particles. From the observed settling rate, an equivalent hydrodynamic diameter and density of clusters of particles were deduced, 38 μm and 2740 kg/m3, respectively. Other work was analyzed with the same procedure; it was concluded that if the stirring prior to settling were intense, then the clusters would be smaller than with weaker stirring. The implications for foundry practice and mechanical properties are discussed.

Similar content being viewed by others

References

D.J. Lloyd:Metal Matrix Composites—Processing, Microstructure and Properties, Proc. 12th Risø Int. Symp. on Materials Scince, Sept. 2–6, 1991, Roskilde, Denmark, pp. 81–99.

G.S. Hanumanth, G.A. Irons, and S. Lafrenier:Metall. Trans. B, 1992, vol. 23B, pp. 753–63.

M. Gallerneault and R.W. Smith:Euromat 91, vol. 1,Advanced Processes, Institute of Materials, 1992, pp. 205–11. London, U.K.

N. Setargew, B.A. Parker, and M.J. Couper:Proc. of Advanced Composites '93, Feb. 15–19, 1993, Wollongong, Australia.

A. Kolsgaard: Ph.D. Thesis, University of Trondheim, 1993.

H. Heywood,Symp. on Interactions between Fluids and Particles, Institute of Chemical Engineers, London, 1962, pp. 1–8.

R. Clift, J.R. Grance, and M.E. Weber:Bubbls, Drops and Particles, Academic Press, New York, NY, 1978.

J.F. Richardson and W.N. Zaki:Trans. Inst. Chem. Eng., 1954, vol. 32, pp. 35–53.

P.U. Foscolo, L.G. Gibilaro, and S.P. Waldram:Chem. Eng. Sci., 1983, vol. 38 (8), pp. 1251–60.

A.S. Michaels and J.S. Bolger:I&EC Fundamentals, 1962, vol. 1, pp. 24–33.

A.E. Fouda and C.E. Capes:Agglomeration '81, O. Molerus and W. Hufnagel, eds., VDI-Gesellschaft Verfahrenstechnik und Chemieingenieurwesen (GVC), Germany, 1981, pp. E34-E50.

A.E. Fouda and C.E. Capes:Powder Technol., 1976, vol. 13, pp. 291–93.

F. Delannay, L. Froyen, and A. Deruyttere:J. Mater. Sci. 1987 vol. 22, pp. 1–16.

G.S. Hanumanth and G.A. Irons:J. Mater. Sci., 1993, vol. 28, pp. 2459–2465.

F. Ajersch and M. Mada: Report No. P1274 for Alcan International Ltd., Ecole Polytechnique, Montreal PQ, Canada, 1989.

Y.P. Fessas and R.H. Weiland:Int. J. Multiphase Flow, 1984, vol. 10 (4) pp. 485–507.

S.F. Corbin and D.S. Wilkinson:Acta Metall Mater., 1994, vol. 42 (4) pp. 1311–18.

Y. Brechet, J.D. Embury, S. Tao, and L. Luo:Acta Metall. Mater., vol. 39 (8), pp. 1781–1991.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Irons, G.A., Owusu-Boahen, K. Settling and clustering of silicon carbide particles in aluminum metal matrix composites. Metall Mater Trans B 26, 981–989 (1995). https://doi.org/10.1007/BF02654099

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02654099