Abstract

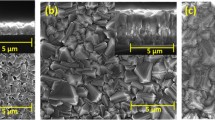

Nodular defect growth is a problem in evaporated, sputtered, chemical vapor deposited (CVD), and electrodeposited films. In this work, the formation and structure of nodular defects in evaporated MgF2 and sputtered Ti were studied and modeled. A structurally similar but fundamentally different runaway growth structure was observed in plasma enhanced CVD (PECVD) Si on Ni. Nodule formation was initiated by seeding the substrate with polystyrene spheres for both the evaporated and sputtered deposits. These nodules grew in a characteristic cone shape with a domed top, and with the nodule separated from the bulk of the film by a low density boundary. Simulation of nodule growth using the SIMBAD Monte Carlo deposition model reproduces the nodular shape as well as the low density region which extends from the seed to the film boundary. Sputtering pressures were found to have little influence on the nodule characteristics, although film thickness and surface diffusion can have important effects. Evidence was found to indicate that the defect structure in the CVD films is due to Ni diffusion into the growing Si film. The structure differs from the physical vapor deposition nodule in two respects: extent of the growth and the adhesion of the defect to the film.

Similar content being viewed by others

References

K.H. Guenther,Applied Optics 20, 1034 (1981).

T. Spalvins and W.A. Brainard,J. Vac. Sci. Technol. 11,1186 (1974).

J.W. Patten,Thin Solid Films 63, 121 (1979).

R. Mattheis, F. Thrum and H.-J. Anklam,Thin Solid Films 188, 355 (1990).

T. Spalvins,Thin Solid Films 64, 143 (1979).

W.R. Holman and F.J. Huegel,J. Vac. Sci. Technol. 11, 701 (1974).

J.A. Thornton,J. Vac. Sci. Technol. 11, 666 (1974).

B. Liao, D.J. Smith and B. McIntyre,Proc. 17th Annual Boulder Damage Symp., Boulder, 1985, ed. H.E. Bennett (National Bureau of Standards Publication no. 746,1988), p. 305.

S. Müller-Pfeiffer and H.-J. Anklam,Vacuum 42,113 (1991).

B. J. Bartholomeusz and T.K. Hatwar,Thin Solid Films 181, 115 (1989).

K.H. Guenther,Proc. of Thin Film Technologies and Special Applications Vol. 678, (SPIE, 1982), p. 9.

T. Smy, K.L. Westra and M.J. Brett,IEEE Trans. Elec. Dev. 37, 591 (1990).

S.K. Dew, M.J. Brett and T. Smy,Jpn. J. Appl Phys. 33, 51 (1994).

M.J. Brett, R.N. Tait, S.K. Dew, S. Kamasz, A.H. Labun and T. Smy,J. Mater. Sci.: Mater, in Elect. 3, 64 (1992).

S.P. Murarka,Silicides for VLSE Applications (Orlando: Academic Press, 1983).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Tait, R.N., Smy, T., Dew, S.K. et al. Nodular defect growth and structure in vapor deposited films. J. Electron. Mater. 24, 935–940 (1995). https://doi.org/10.1007/BF02652964

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF02652964