Abstract

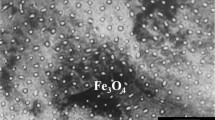

The mechanism of the gaseous reduction of hematite grains to magnetite was studied. Grav-imetric measurements were carried out for the reduction of Carol Lake hematite pellets and grains in CO-CO2 atmospheres over the temperature range 500 to 1100°C. The pore size distribution in the reduced magnetite was measured by mercury porosimetry. Partially reduced grains were examined by optical microscopy. At temperatures below 800°C, the reduction of a hematite grain to magnetite occurred at a well-defined shrinking-core inter-face. The average pore size in magnetite formed at 600°C was found to be 0.03 µm. An es-timate of the rate of CO diffusion through pores of this size indicated that the reaction rate at 600°C was controlled by a step near the hematite-magnetite interface. At temperatures above 800°C, the reaction mechanism became altered due to the preferential growth of magnetite along a single direction in each hematite grain. The reduction rate decreased with an increase in temperature, and no microporosity was present in magnetite formed at 1000°C and above. It was postulated that the reaction rate was controlled by the rate of formation of fresh nuclei and by their rate of subsequent growth.

Similar content being viewed by others

References

R. L. Bleifuss:Blast Furnace Technology, J. Szekely, ed., pp. 1–34, Dekker, New York, 1972.

E. T. Turkdogan and J. V. Vinters:Met. Trans., 1971, vol. 2, pp. 3175–88.

R. D. Walker, N. S. Ford, and D. L. Carpenter:Trans. Iron Steel Inst. Jap., 1971, vol. 11, pp. 473–76.

G. Thaning:Jernkontorets Ann., 1971, vol. 155, pp. 47–92.

H. Brill-Edwards, B. L. Daniell, and R. L. Samuel:J. Iron Steel Inst., 1965, vol. 203, pp. 361–68.

A. G. Matyas and A. V. Bradshaw:Ironmaking and Steelmaking, 1974, vol. 1, no. 3, pp. 180–87.

A. G. Matyas: Ph.D. Thesis, Univ. of London, 1972.

R. H. Spitzer, F. S. Manning, and W. O. Philbrook:Trans. TMS-AIME, 1966, vol. 236, pp. 726–42.

A. Muan and E. F. Osborn:Phase Equilibria Among Oxides in Steelmaking, pp. 49–52, Addison-Wesley, Reading, 1965.

L. Bogdandy and H. J. Engell:The Reduction of Iron Ores, Springer-Verlag, Berlin, 1971.

K. Mayer, H. Rausch, and M. Ottow:Stahl Eisen, 1967, vol. 87, pp. 654–60.

J. L. Kenty and J. P. Hirth:Surface Sci., 1969, vol. 15, pp. 403–24.

B. C. H. Steele:Physical Chemistry of Process Metallurgy—The Richardson Conference, J. H. E. Jeffes and R. J. Tait, eds., p. 1, Inst. Mining Met., London, 1974.

C. N. Satterfield and T. K. Sherwood:The Role of Diffusion in Catalysis, Addison-Wesley, 1963.

Author information

Authors and Affiliations

Additional information

Formerly Professor of Applied Metallurgy, Imperial College

Rights and permissions

About this article

Cite this article

Bradshaw, A.V., Matyas, A.G. Structural changes and kinetics in the gaseous reduction of hematite. Metall Trans B 7, 81–87 (1976). https://doi.org/10.1007/BF02652822

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF02652822