Abstract

The importance of strain hardening and strain-rate hardening in sheet tensile tests has been investigated using finite-element modeling (FEM). A Hollomon-type material law was examined with n-values (logarithmic work hardening rate) between 0.0 and 0.5 andm- values (logarithmic strainrate sensitivity) between -0.002 and 0.3. A von Mises yield condition with isotropic hardening rule completed the material model. The results of these simulations showed that, as expected, the uniform elongation(e u ) depends mainly onn, with a small dependence onm. The post-uniform elongation (e f —e u ;e f = total elongation) depends on bothn andm, and is highly nonlinear in either variable for large parametric values. That is, combined increases ofn andm extend ductility more than the additive increase expected from separate effects. Earlier presumptions thatn is unimportant in the post-uniform region appear incorrect. Approximate relations between (e f ,e u ) and (n,m) were developed quantitatively. These relations have been compared with superplastic data in the literature and appear to agree well, given uncertainties in specimen geometry and test procedure.

Similar content being viewed by others

References

A. Considére:Ann. des Ponts et Chaussees, 1885, vol. 9, ser. 6, p. 574.

E.W. Hart:Acta Metall., 1967, vol. 15, pp. 351–55.

E. Duncombe:Inter. J. Mech. Sci., 1972, vol. 14, pp. 325–37.

A. K. Ghosh:Metall. Trans. A, 1977, vol. 8A, pp. 1221–32.

J.W. Hutchinson and K.W. Neale:Acta Metall., 1977, vol. 7A, pp. 839–46.

U.F. Kocks, J.J. Jonas, and H. Mecking:Acta Metall., 1979, vol. 27, pp. 419–32.

F. A. Nicois:Acta Metall., 1980, vol. 28, pp. 663–73.

I.H. Lin, J. P. Hirth, and E. W. Hart:Acta Metall., 1981, vol. 29, pp. 819–27.

D. Lee and W. A. Backofen:Trans. AIME, 1967, vol. 239, p. 1034.

D. A. Woodford:Trans. Am. Soc. Metals, 1969, vol. 62, pp. 291–93.

G. Rai and N.J. Grant:Metall. Trans. A, 1975, vol. 6A, pp. 385–90.

A.K. Ghosh:J. Eng. Mat. Tech. Trans. ASME, 1977, vol. 99, pp. 264–74.

J.H. Hollomon:Trans. AIME, 1945, vol. 162, pp. 268–90.

R. Hill:Math. Proc. Cambridge Philos. Soc., 1979, vol. 85, pp. 179–91.

P. B. Mellor and A. Parmer:Mechanics of Sheet Metal Forming, D.P. Koistinen and N.-M. Wang, eds., Plenum Press, New York, NY, 1978, p. 53.

K. Chung and R.H. Wagoner:Metall. Trans. A, 1986, vol. 17A, pp. 1632–33.

N.-M. Wang:Numerical Methods in Industrial Forming Processes, J.F.T. Pittman, R.D. Wood, J.M. Alexander, and O.C. Zienkiewicz, eds., Pineridge Press, Swansea, U.K., 1982, p. 797.

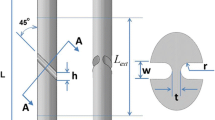

Tensilkut Engineering, Danbury, CT 06810.

S.L. Semiatin and J.J. Jonas:Formability and Workability of Metals, ASM, Metals Park, OH.

P. W. Bridgeman:Trans. ASM, 1944, vol. 32, pp. 553–74.

Author information

Authors and Affiliations

Additional information

K. CHUNG, formerly Postdoctoral Research Associate, Department of Metallurgical Engineering, The Ohio State University

Rights and permissions

About this article

Cite this article

Chung, K., Wagoner, R.H. Effects of work-hardening and rate sensitivity on the sheet tensile test. Metall Trans A 19, 293–300 (1988). https://doi.org/10.1007/BF02652538

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02652538