Abstract

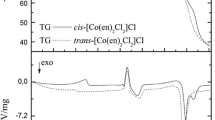

The carbon potentials corresponding to the two-phase mixtures Cr + Cr23C6, Cr23C6 + Cr7C3, and Cr7C3 + Cr3C2 in the binary system Cr-C were measured in the temperature range 973 to 1173 K by using the methane-hydrogen gas equilibration technique. Special precautions were taken to prevent oxidation of the samples and to minimize thermal segregation in the gas phase. The standard Gibbs energies of formation of Cr23C6, Cr7C3, and Cr3C2 were derived from the measured carbon potentials. These values are compared with those reported in the literature. The Gibbs energies obtained in this study agree well with those obtained from solid-state cells incorporating CaF2 and ThO2(Y2O3) as solid electrolytes and sealed capsule isopiestic measurements reported in the literature.

Similar content being viewed by others

References

Binary Alloy Phase Diagrams, T.B. Massalski, H. Okamoto, P.R. Subramanian, and L. Kacprazak, eds., ASM, Metals Park, OH, 1986, vol. 1.

A.D. Kulkarni and W.L. Worrell:Metall. Trans., 1972, vol. 3, pp. 2363–70.

K.K. Kelley, F.S. Boericke, G.E. Moore, E.H. Huffman, and W.M. Bangert: U.S. Bureau of Mines Technical Report No. 662, U.S. Government Printing Office, Washington, DC, 1949.

M. Gleiser:J. Phys. Chem., 1965, vol. 69, pp. 1771–72.

H. Kleykamp:Ber. Bunsenges. Phys. Chem., 1969, vol. 73, pp. 354–58.

R.G. Coltters and G.R. Belton:Metall. Trans. B, 1984, vol. 15B, pp. 517–21.

H. Mabuchi, N. Sano, and Y. Matsushita:Metall Trans., 1971, vol. 2, pp. 1503–05.

S. Du, S. Seetharaman, and L.-I. Staffansson:Metall. Trans. B, 1989, vol. 20B, pp. 911–17.

Y.J. Bhatt, R. Venkataramani, Y.S. Sayi, and S.P. Garg:Met, Mater. Processes, 1990, vol. 2 (1), pp. 49–58.

V.I. Alekseev and L.A. Shwratsman:Fiz.-Khim. Osnovy Met. Protsessov, Komis. Po Fiz.-Khim. Osnovam Proizv Stali, 1964, pp. 414–21.

M. Small and E. Ryba:Metall. Trans. A, 1981, vol. 12A, pp. 1389–96.

A.D. Mah: U.S. Bureau of Mines Technical Report No. 7217, U.S. Government Printing Office, Washington, DC, 1969.

W.M. Dawson and F.R. Sale:Metall. Trans. A, 1977, vol. 8A, pp. 15–18.

S. Anthonysamy: Master's Thesis, Indian Institute of Science, Bangalore, India, 1994.

M.W. Chase, C.A. Davies, J.R. Dourey, D.J. Frury, R.A. McDonald, and A.N. Syverud:J. Phys. Chem. Ref. Data, 1985, vol. 14, pp. 535, 600, 652, 673, 684 and 928.

S. Du:Scand. J. Metall, 1989, vol. 18, pp. 226–34.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Anthonysamy, S., Ananthasivan, K., Kaliappan, I. et al. Gibbs energies of formation of chromium carbides. Metall Mater Trans A 27, 1919–1924 (1996). https://doi.org/10.1007/BF02651941

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02651941