Abstract

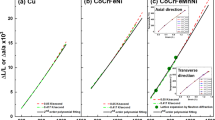

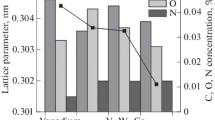

A modified mass-loss measurement technique is employed, for the direct,in- situ determination of the metal vacancy formation in (Hg1x2212;itxCd x )1−y Te y (s) withx = 0.2 and 0.4. Forx = 0.2, the metal vacancy concentrations are determined between 336 and 660° C for three different compositions(y) within the homogeneity region and range from 2.4 to6.8 x 1019cm−3. The enthalpy of formation of a singly-ionized metal vacancy is derived to be between 0.17 and 0.45 eV depending upon the deviation from stoichiometry (compositiony). Forx= 0.4, three samples of different y-values give the metal vacancy concentrations from 1.9 to 5.5 x 1019cm−3 between 316 and 649° C, and the enthalpy of vacancy formation between 0.25 and 0.40 eV. Compared to the recent data on HgTe(s), these experimental results show a slight but significant decrease in the enthalpy of vacancy formation from HgTe to Hg0.8Cd0.2Te, which supports theoretical predictions of the bond weakening effect of Cd for the latter alloy system. Based on the simultaneously determined equilibrium Hg partial pressures within the homogeneity range, the vacancy concentration-partial pressure isotherms are constructed. The Hg partial pressures are also measured along the three-phase boundaries of the solid solutions of bothx = 0.2 and 0.4, and these are in close agreement with published data obtained by optical absorption measurements.

Similar content being viewed by others

References

W. D. Lawson, S. Nielson, E. H. Putley, and A. S. Young, J. Phys. Chem. Solids9, 325 (1959).

J. L. Schmit, J. Cryst. Growth65, 249 (1983).

M. A. Herman and M. Pessa, J. Appl. Phys.57, 2671 (1985).

H. Wiedemeier and D. Chandra, Z. Anorg. Allg. Chem.488, 137 (1982).

H. Wiedemeier and A. E. Uzpurvis, J. Electrochem. Soc.130, 252 (1983).

H. Wiedemeier, A. E. Uzpurvis, and D. C. Wang, J. Cryst. Growth65, 474 (1983).

H. Wiedemeier and A. E. Uzpurvis, Z. Anorg. Allg. Chem.510, 199 (1984).

D. Chandra and H. Wiedemeier,ibid. 545, 98 (1987).

H. Wiedemeier and D. Chandra,ibid. 545, 109 (1987).

H. Wiedemeier and W. Palosz, J. Cryst. Growth96, 933 (1989).

P. W. Kruse, in “Semiconductors and Semimetals”18, p. 1, Eds. R. K. Willardson and A. C. Beer, Academic Press, New York (1981).

H. R. Vydyanath, J. Electrochem. Soc.128, 2609 (1981).

R. A. Reynolds, M. J. Brau, H. Kraus, and R. T. Bate, J. Phys. Chem. Solids32, Suppl. 1, 511 (1971).

H. R. Vydyanath, J. Danovan, and D. A. Nelson, J. Electro- chem. Soc.128, 2625 (1981).

J. L. Schmit and E. L. Stelzer, J. Electron. Mater.7, 65 (1978).

D. T. Cheung, J. Vac. Sci. Tech.A3, 128 (1985).

S. S. Chern, H. R. Vydyanath, and F. A. Kröger, J. Solid State Chem.14, 33 (1975).

S. S. Chern and F. A. Kröger,ibid. 14, 44 (1975).

Y. G. Sha and H. Wiedemeier, J. Electron. Mater.19, 159 (1990).

J. H. E. Jeffes and T. N. R. Marples, J. Cryst. Growth17, 46 (1972).

J. P. Schwartz, T. Tung, and R. F. Brebrick, J. Electrochem. Soc.128, 438 (1981).

T. Tung, L. Golonka, and R. F. Brebrick,ibid. 128, 451 (1981).

H. Wiedemeier, S. B. Trivedi, R. C. Whiteside, and W. Pa- Losz,ibid. 133, 2399 (1986).

H. Wiedemeier and C. L. Chang, J. Less-Common Metals137, 375 (1988).

J. C. Wooley and B. Ray, J. Phys. Chem. Solids13, 151 (1960).

R. F. Brebrick, C.-H. Su, and P.-K. Liao, in “Semiconductors and Semimetals”19, p. 171, Eds.R. K. Willardson and A. C. Beer, Academic Press, New York (1983).

S. Sugawara, T. Sato, and T. Minamiyama, Bull. JSME5, 711 (1962).

A. Sher, A.-B. Chen, W. E. Spicer, and C.-K. Shih, J. Vac. Sci. Tech.A3, 105 (1985).

K. C. Haas and D. Vanderbilt,ibid. A5, 3019 (1987).

H. Rodot, R. Triboulet, and A. Hruby, in “Lattice Defects in Semiconductors,” p. 238, ed. R. R. Hasiguti, Univ. Tokyo Press, Tokyo (1968).

C. L. Wang, S. Wu, and D. S. Pan, J. Vac. Sci. Tech.A1, 1631 (1983).

F. Bailly, in “Lattice Defects in Semiconductors,” p. 231, ed. R. R. Hasiguti, Univ. Tokyo Press, Tokyo (1968).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Wiedemeier, H., Sha, Y.G. The direct determination of the vacancy concentration andP-T phase diagram of Hg0.8Cd0.2Te and Hg0.6Cd0.4Te by dynamic mass-loss measurements. J. Electron. Mater. 19, 761–771 (1990). https://doi.org/10.1007/BF02651382

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF02651382