Abstract

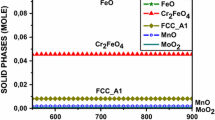

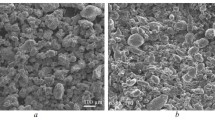

Recent efforts to explore the possibility of extending the service of alumina-based refractories into basic steelmaking operations have involved the application of a basic oxide veneer to both fireclay and high-alumina substrates. Because these investigations used a mineralogically complex system consisting of mixtures of commercial refractories and coatings, the nature of the chemical/mineralogical changes that occurred due to the presence of various metal oxides was often difficult to determine. Thus, the present work was undertaken to establish the extent of chemical/mineralogical reaction that might be expected when dissimilar pellets of high-purity single oxides were placed in pressureless contact for known reaction times at known temperatures. Results for the systems , and MgO-Fe showed significant diffusion of chromium into both Fe, as well as iron into MgO after 3 h at 1450 °C. Also, for mixtures of Al and MgO, over 29% spinel formation was evident, even at 1200 °C for 3 h. However, because most couples in the solid state did not remain joined on cooling in spite of the extensive reaction, it would appear that to achieve good bonding, liquid or transient liquid sintering is a prerequisite to the formation of an adherent oxide veneer on a commercial refractory.

Similar content being viewed by others

References

R.J. Fruehan, Ladle Metallurgy Principles and Practices,Iron Steel Soc., 1985, p 149

E.T. Turkdogan, Slags and Fluxes for Ferrous Ladle Metallurgy,Ironmaking Steelmaking, Vol 12 (No. 2), 1986, p 64–77

W.F. Caley, L.E. Kanary, and D.B. Clarke, Chemical and Mineralogical Examination of a 4Cr2O3·MgO Coating Applied to a Bloating Fireclay Brick,Can. Metall. Quart., Vol 26 (No. 3), 1987, p 259–264

W.F. Caley, L.E. Kanary, D.B. Clarke, and S.H. Didyk, Reduction of Chemical Corrosion in Transfer Ladles by Application of an Oxide Ceramic Coating, inAdvances in Refractories for the Metallurgical Industries, M.A.J. Rigaud, Ed., Pergamon Press, 1987, p 299-303

W.F. Caley, S.H. Didyk, and P.W. Kingston,“ Reduction of Slag-Line Corrosion in Secondary Steelmaking Ladles,” UNITECR ’89 Proceedings, The American Ceramic Society, 1989, p 430–441

E.N. Bunting,Bur. Stand. J. Res., Vol 6 (No. 6), 1931, p 317

A. Maun and S. Sómiya,J. Am. Ceram. Soc., Vol 43 (No. 4), 1960, p 207

A. Alper, R.N. McNally, P.G. Ribbe, and R.C. Coman,J. Am. Ceram. Soc., Vol 45 (No. 6), 1962, p 264

D.M. Roy, R. Roy, and E.F. Osborn,J. Am. Ceram. Soc., Vol 36 (No. 5), 1953, p 149

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Cameron, J., Caley, W.F. Dry sintering of refractory oxides at elevated temperatures. JMEP 2, 733–737 (1993). https://doi.org/10.1007/BF02650064

Issue Date:

DOI: https://doi.org/10.1007/BF02650064