Abstract

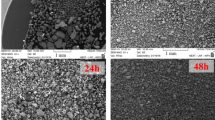

A systematic investigation was undertaken to compare the effect of processing on the phase relations and microstructure of 66Ti-22Al-12Nb (in at. pct) alloy. The alloy was processed by three different routes: (1) cold pressing (CP) followed by reaction sintering; (2) CP followed by hot pressing (HP) followed by sintering; and (3) arc melting (AM), hydride-dehydride processing to make the alloy powder followed by cold isostatic pressing and then sintering. The samples were analyzed by X-ray diffraction (XRD); optical microscopy, scanning electron microscopy-energy dispersive spectroscopy (SEM-EDS), and electron microprobe analysis (EPMA). The analyses showed that all the processing methods have resulted in the same phases, but the AM route resulted in an equiaxed microstructure, whereas the other two methods resulted in a lamellar microstructure. This refinement in microstructure was attributed to the hydride-dehydride processing step of the AM route.

Similar content being viewed by others

References

J.M. Larsen, K..A. Williams, S.J. Balsone, and M.A. Stucke:Proc. High Temperature Aluminides and Intermetallics, S.H. Whang, C. T. Liu, D.P. Pope, and J.O. Stiegler, eds., TMS, Warrendale, PA, 1991, pp. 521–56.

J.H. Westbrook:Intermetallic Compounds, Wiley Publishing, New York, NY, 1967.

G. Kumar, P.R. Narayanan, K.G. Reddy, S. Arumugam, and T.S. Lakshmanan:J. Pract. Metallogr., 1992, vol. 29, pp. 213–19.

W.B. Pearson:A Handbook of Lattice Spacings and Structures of Metals and Alloys, Pergamon Press, Elmsford, NY, 1967, vol. 2, p. 126.

J.R. Groza, S.H. Risbud, and K. Yamazaki:Proc. Plasma Synthesis and Processing of Materials, K. Upadhya, ed., TMS, Warrendale, PA, 1993, pp. 85–93.

F.H. Froes, C. Suryanarayana, and D. Elizer:J. Mater. Sci., 1992, vol. 27, p. 5113.

R.G. Rowe:Proc. High Temperature Aluminides and Intermetallics, S.H. Whang, C.T. Liu, D.P. Pope, and J.O. Stiegler, eds., TMS, Warrendale, PA, 1991, pp. 375–401.

Phase Diagrams of Binary Titanium Alloys, J.L. Murray, ed., ASM INTERNATIONAL, Metals Park, OH, 1987, pp. 12–24.

L.A. Bendersky and W.J. Boettinger:Mater. Res. Soc. Proc, 1989, vol. 133, pp. 45–50.

D.T. Hoelzer and F. Ebrahimi:Proc. High Temperature Niobium Alloys, J.J. Stephens and I. Ahmad, eds., TMS, Warrendale, PA, 1991, pp. 105–19.

J.H. Perepezko, Y.A. Chang, L.E. Seitzman, J.C. Lin, N.R. Bonda, T.J. Jewett, and J.C. Mishurda:Proc. High Temperature Aluminides and Intermetallics, S.H. Whang, C.T. Liu, D.P. Pope, and J. O. Stiegler, eds., TMS, Warrendale, PA, 1991, pp. 19–47.

U.R. Kattner and W.J. Boettinger:Mater. Sci. Eng., 1992, vol. A152, pp. 9–17.

R.G. Rowe:Adv. Mater. Processes, 1992, vol. 141 (3), p. 33.

S.G. Kumar and R.G. Reddy:Proc. Extractive Metallurgy of Copper, Nickel and Cobalt, R.G. Reddy and R.N. Weizenbach, eds., TMS, Warrendale, PA, 1993, pp. 1101–23.

R.G. Reddy and K.N. Hebbar:Proc. Electron Beam Melting and Refining—State of the Art 1991, R. Bakish, ed., Bakish Materials Corporation, Englewood, NJ, 1991, pp. 284–91.

D.M. Kocherginsky and R.G. Reddy:Proc. Control of Interfaces in Metal and Ceramic Composites, R.Y. Lin and S.G. Fishman, eds., TMS, Warrendale, PA, 1994, pp. 71–79.

S.G. Kumar, R.G. Reddy, and L. Brewer:J. Phase Equil, 1994, vol. 15, pp. 279–84.

S.G. Kumar, R.G. Reddy, J. Wu, and J. Holthus:J. Mater. Eng. Perform., 1995, vol. 4, pp. 63–69.

S.G. Kumar and R.G. Reddy:Proc. Synthesis/Processing of Lightweight Metallic Materials, F.H. Froes, C. Suryanarayana, and C.M. Ward-Close, eds., TMS, Warrendale, PA, 1995, pp. 129–39.

R. Strychor, J.C. Williams, and W.A. Soffa:Metall. Trans. A, 1988, vol. 19A, pp. 225–34.

S.M.L. Sastry and H.A. Lipsitt:Metall. Trans. A, 1977, vol. 8A, pp. 1543–52.

A.K. Gogia, T.K. Nandy, K. Muraleedharan, and D. Banerjee:Mater. Sci. Eng., 1992, vol. A159, pp. 73–86.

P.K. Brindley, S.L. Draper, M.V. Nathal, and J.I. Eldridge:Proc. Fundamental Relationships between Microstructure and Mechanical Properties of Metal Matrix Composites, P.K. Liaw and M.N. Gungar, eds., TMS, Warrendale, PA, 1990, p. 387.

H. Ward, J.C. Williams, A.W. Thompson, D.G. Rosenthal, and F.H. Froes:Proc. 6th World Conf. on Titanium, P. Lacombe, R. Tricot, and G. Beranger, eds., Societe Francaise de Metallurgie, Les Editions de Physique, Les Ulis, France, 1989, pp. 1103–08.

F.V. Lenel:Powder Metallurgy: Principles and Applications, Metal Powder Industries Federation, Princeton, NJ, 1980.

Author information

Authors and Affiliations

Additional information

Formerly Professor with the Dept. of Chemical and Metallurgical Engineering, University of Nevada.

Rights and permissions

About this article

Cite this article

Kumar, S.G., Reddy, R.G. Microstructure and phase relations in a powder-processed Ti-22AI-12Nb Alloy. Metall Mater Trans A 27, 1121–1126 (1996). https://doi.org/10.1007/BF02649780

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02649780