Abstract

The effects of expulsion on microstructure and tensile shear strength of spot welds have been investigated for a high-strength cold rolled sheet steel. Spot welds with expulsion are characteristic for a “double im-age” near the fusion line, an equiaxed dendritic grain zone along the faying surface, and deep indenta-tions on the outer surfaces. Microstructural examinations and tensile shear tests of spot welding specimens were conducted to determine the correlation between microstructure and strength. It was found that the equiaxed dendritic structure was associated with significant solidification cracking. Frac-tography on tensile specimens reveals that brittle failure is associated with an equiaxed microstructure. Furthermore, the surface indentation will change the stress at the nugget edge, and deep surface inden-tations are expected to promote premature failure.

Similar content being viewed by others

References

W.F. Savage, E.F. Nippes, and F.A. Wassell, Dynamic Contact Resistance of Series Spot Welds,Weld. J., Vol 57, 1978. p 43s-50s

D.W. Dickeson, J.E. Franklin, and A. Stanya, Characterization of Spot Welding Behavior of Dynamic Electrical Monitoring,Weld. J., Vol 59, 1980, p 170s-176s

J.G. Kaiser, G.J. Dunn, and T.W. Eager, The Effect of Electrical Resistance on Nugget Formation During Spot Welding,Weld. J.. Vol 61, 1982, p 167s-174s

H.A. Nied, The Finite Modeling of the Resistance Spot Welding Process,Weld. J., Vol 63, 1984, p 123s-132s

J.E. Gould, An Examination of Nugget Development During Re- sistance Spot Welding Using Both Experimental and Analytical Techniques,Weld. J., Vol 66, 1987. p 1s-10s

Z.Y. Han, J.E. Indacochea, and C.E. Chen, Resistance Spot Weld- ing: A Heat Transfer Study,Weld. J., Vol 68, 1989, p 363s-371 s

Metals Handbook, Vol 6, 8th ed., American Society for Metals, p 478

M. Kimchi, Spot Weld Properties When Welding with Expul- sion—A Comparative Study,Weld. J., Vol 63 (No. 2), 1984, p 58s-63s

K.C. Wu, Electrode Indentation Criterion for Resistance Spot Welding,Weld. J., Vol 47 (No. 10), 1968, p 472s-478s

M. Anastassiou et al., Residual Stresses and Microstructure Dis- tribution in Spot-Welded Steel Sheets: Relation with Fatigue Be- havior,Mater. Sci. Eng., Vol A125, 1990, p 141–156

M.K. Kassir and G.G. Sih, External Elliptical Crack in Elastic Solid,Int. J. Fract. Mech., Vol 4 (No. 41), 1968, p 347–356

L.P. Pook, “Approximate Stress Intensity Factors for Spot and Similar Welds,” NEL Report No. 588, 1975

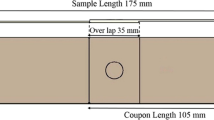

D.J. Chang and R. Muki, Stress Distribution in a Lap Joint Under Tension Shear,Int. J. Solids Struct.. Vol 10. 1974. p 503–5 17

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Han, Z., Indacochea, J.E. Effects of expulsion in spot welding of cold rolled sheet steels. JMEP 2, 437–444 (1993). https://doi.org/10.1007/BF02648832

Issue Date:

DOI: https://doi.org/10.1007/BF02648832