Abstract

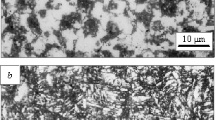

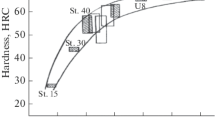

A process involving the use of an argon thermal plasma jet to facilitate selective hardening of a high- carbon steel (E52100) has been studied experimentally. Cylindrical hollow specimens (approximately 8.0 cm OD by 6.0 cm ID by 9.0 cm long) were treated during this process by rapidly heating the central section of these samples to 870 °C, soaking at 870 °C for 1.0 to 2.0 min and then rapidly quenching the samples. All samples were continuously turned at an angular velocity of about 6 rev/sec during each trial run to promote uniform changes in temperature. A noncontact infrared sensor was also used to monitor and facilitate specimen temperature control throughout the heating and soaking phases of each test trial. The heat treated specimens were sectioned longitudinally, polished, and used to obtain microhardness profiles for several of these heat treated specimens. This work indicated that complete and relatively uniform through hardening was achieved in all of the test specimens. A significant advantage of this process over other more conventional hardening methods involves the very rapid heat transfer rates that are possible between a plasma jet flame and the heated object. An additional and somewhat related advantage is that undesirable overheating of specimen sections (adjacent to the heat treated zone) by conduction can be minimized. This effect may permit the production of selectively hardened steel objects that cannot be produced using more conventional technology.

Similar content being viewed by others

References

P.M. Unterweiser, H.E. Boyer, and J.J. Kubbs, Ed.,Heat Treater’s Guide, ASM, Metals Park, 204 (1985).

R.J. Kar, R.M. Horn, and V.F. Zackay,Metall. Trans., 10A(11), 1711–1717(1979).

K. Nakazawa and G. Krauss,Metall. Trans., 9A(5), 681–689 (1978).

H.E. Boyer,Practical Heat Treating, ASM, Metals Park, 131 (1984).

D. Wang, H. Hua, M.E. Fine, and H.S. Cheng,Mater. Sci. Eng., A118, 113–120(1989).

J.M. Beswick,Metall. Trans., 20A(10), 1961–1973(1989).

C.A. Stickeis,Wear, 9S(1-3), 199–210(1984).

C.A. Stickeis and A.M. Janotik,Metall. Trans., 11A(3), 467–473 (1980).

F.W. Giacobbe, U.S. Pat. No. 4,872,926 (1989).

F.W. Giacobbe,High Temp. Technol, 8(1), 3–8 (1990).

F.W. Giacobbe, High Temp. Technol., 7(1), 11–16(1989).

Corning Technical Bulletin, Macor Machinable Glass Ceramic, Corning Glass Works, Corning, NY.

D.S. Clark and W.R. Varney,Physical Metallurgy for Engineers, 2nd ed., American Book Co., New York, 143–146 (1969).

G. Krauss,Principles of Heat Treatment of Steel, ASM, Metals Park, 129(1985).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Giacobbe, F.W. Selective hardening in E52100 steel. JMEP 1, 267–274 (1992). https://doi.org/10.1007/BF02648627

Issue Date:

DOI: https://doi.org/10.1007/BF02648627