Abstract

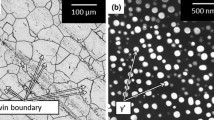

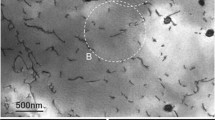

The effect of brittle coating precracking on the fatigue behavior of a high-activity aluminide-coated single-crystal nickel-base superalloy has been studied using hollow cylindrical specimens at test temperatures of 600 °, 800 °, and 1000 °. Three types of precrack were studied: narrow precracks formed at room temperature, wide precracks formed at room temperature, and narrow precracks formed at elevated temperature. The effect of precracking on fatigue life at 600 ° was found to depend strongly on the type of precrack. No failure was observed for specimens with narrow room-temperature precracks because of crack arrestvia an oxidation-induced crack closure mechanism, while the behavior of wide precracks and precracks formed at elevated temperature mirrored the non-precracked behavior. Crack retardation also occurred for narrow room-temperature precracks tested at 800 °—in this case, fatigue cracks leading to failure initiated in a layer of recrystallized grains on the inside surface of the specimen. A significant reduction in fatigue life at 800 ° relative to non-precracked specimens was observed for wide precracks and elevated temperature precracks. The presence of precracks bypassed the initiation and growth of coating fatigue cracks necessary for failure in non-precracked material. No effect of precracking was observed at 1000 °.

Similar content being viewed by others

References

T.C. Totemeier and J.E. King:Metall. Trans. A, 1996, vol. 27A, pp. 353–61.

T.E. Strangman and S.W. Hopkins:Bull. Am. Ceram. Soc, 1976, vol. 55, pp. 304–07.

J. Gayda, T.P. Gabb, and R.V. Miner: inSuperalloys 1988, S. Reichman, D.N. Duhl, G. Maurer, S. Antolovich, and C. Lund, eds., TMS, Warrendale, PA, 1988, pp. 575–84.

S. Suresh:Fatigue of Materials, Cambridge University Press, Cambridge, United Kingdom, 1992, pp. 136–37.

S. Suresh, G.F. Zamiski, and R.O. Ritchie:Metall. Trans. A, 1981, vol. 12A, pp. 1435–43.

D.P. Rooke and D.J. Cartwright:Compendium of Stress Intensity Factors, Her Majesty's Stationery Office, London, 1976, pp. 237–38.

Rolls-Royce plc, Derby, United Kingdom, personal communication, 1992.

R.E. Reed-Hill:Physical Metallurgy Principles, 2nd ed., PWS-Kent Publishing Co., 1973, pp. 267-326.

M. Gell and G.R. Leverant: inFatigue at Elevated Temperatures, ASTM STP 520, ASTM, Philadelphia, PA, 1973, pp. 37–67.

Author information

Authors and Affiliations

Additional information

Formerly Research Student, Department of Materials Science and Metallurgy, University of Cambridge.

Formerly Lecturer, Department of Materials Science and Metallurgy, University of Cambridge CB2 3QZ, United Kingdom.

Rights and permissions

About this article

Cite this article

Totemeier, T.C., Gale, W.F. & King, J.E. Isothermal fatigue of an aluminide-coated single-crystal superalloy: Part II. effects of brittle precracking. Metall Mater Trans A 27, 363–369 (1996). https://doi.org/10.1007/BF02648413

Issue Date:

DOI: https://doi.org/10.1007/BF02648413