Abstract

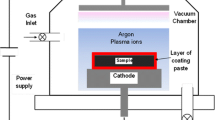

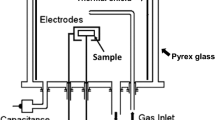

This article deals with various aspects of nitrocarburizing of AISI 1010 steel by DC plasma at 600 °C. The initial stages of nitride formation and the effects of surface bombardment by hydrogen plasma species, as well as the effect of treatment current density on the surface morphology, were investigated in detail. The results show that in the pearlitic region carbides are removed during treatment in hydrogen plasma and that the current density influences the surface morphology significantly. A porous surface formed in a 1-minute treatment under high current density (8 mA/cm2), whereas a lower current density (2.4 mA/cm2) resulted in a highly stressed surface attributed to uneven thermal gradients. Iron nitrides were identified on the surface in either set of conditions. A pure epsilon compound layer was obtained by plasma nitrocarburizing for 6 hours and quenching. The pores in this layer are discussed in view of the 1-minute treatment results and are also compared to those observed in a nitriding treatment. The lack of carbon species in the nitriding plasma results in different mechanisms for pore formation and growth during the treatment. These results are discussed in view of current models for plasma nitriding and gas nitrocarburizing.

Similar content being viewed by others

References

R.R. Manory:Mater. Manuf. Proc., 1990, vol. 5 (3), pp. 445–70.

A.M. Staines and T. Bell:Thin Solid Films, 1981, vol. 86, pp. 201–11.

M.H. Jacobs, T.J. Law, and F. Ribet:Surf. Eng., 1985, vol. 1 (2), pp. 105–13.

J.G. Conybear and B. Endenhofer:Ind. Heat, 1989, Mar., pp. 18–21.

J. Kölbel:Forschungsberichte des Landes Nordhein-Westfalen, West-Deutscher-Verlag. Köln, Germany, 1965, [No. 1555.].

M. Hudis:J. Appl. Phys., 1973, vol. 44 (4), pp. 1489–96.

A. Szabo and H. Wilhelmi:Plas. Chem. Plas. Process., 1984, vol. 4 (2), pp. 89–103.

B. Xu and Y. Zhang:Surf. Eng., 1989, vol. 3 (3), 1989, pp. 226–32.

E. Haruman, T. Bell, and Y. Sun:Surf. Eng., 1992, vol. 8 (4), pp. 275–82.

J. Hadfield: Master’s Thesis, University of Birmingham, Birmingham, England, 1986.

K.H. Jack:Proc. R. Soc. A, 1948, vol. 195, pp. 41–45.

J.L. Marchand, H. Michel, M. Gantois, and A. Ricard:Proc. Int. Conf. on Ion Nitriding, T. Spalvins, ed., ASM, Metals Park, OH, 1986, pp. 53–60.

R. Manory:J. Electrochem. Soc., 1986, vol. 8, p. 1752.

Y. Khait, A. Inspektor, and R. Avni:Thin Solid Films, 1980, vol. 72, p. 239.

R. Avni, V. Carmi, I. Rosenthal, R. Manory, and A. Grill:Thin Solid Films, 1983, vol. 107, pp. 235–44.

Y. Catherine, G. Turban, and B. Grollean:Thin Solid Films, 1981, vol. 76, pp. 13–33.

T. Lampe, S. Eisenberg, and G. Laudien:Surf. Eng., 1993, vol. 9 (1), pp. 69–76.

C.V. Robino and O.T. Inal:Mater. Sci. Eng., 1983, vol. 59, pp. 79–90.

T. Spalvins:Ion Nitriding and Ion Carburising, T. Spalvins, ed., ASM INTERNATIONAL, Metals Park, OH, 1989, pp. 1–4.

Y. Inokuti, N. Nishida, and N. Ohashi:Metall. Trans. A, 1975, vol. 6A, pp. 773–84.

B. Prenosil:Strjirenstvi, 1973, vol. 23 (9), pp. 555–62.

E.J. Mittemeijer, A.B.P. Vogels, and P.J. Van Der Schaaf:J. Mater. Sci., 1980, vol. 15, pp. 3129–40.

N.L. Loh:Proc. 2nd Aus. Int. Conf. on Surface Engineering, C. Subramanian and K. Strattford, eds., Surface Engineering Research Group, University of South Australia, Adelaide, South Australia, March, 1994, pp. C442-C453.

S. Li, R.R. Manory, and J.H. Hensler:Surf. Coat. Technol., 1995, vol. 71, pp. 112–20.

S. Li and R.R. Manory: Australian Provisional Patent Application PM6183/94.

H.C.F. Rozendaal, P.F. Colijin, and E.J. Mittemeijer:Surf. Eng., 1985, vol. 1 (1), pp. 30–42.

M.A.J. Somers and E.J. Mittemeijer:Surf. Eng., 1987, vol. 3 (2), pp. 123–37.

B. Prenosil:Harterei-Tech. Mitt., 1973, vol. 28, pp. 157–64.

A. Wells: Ph.D. Thesis, University of Liverpool, Liverpool, England, 1982.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Li, S., Manory, R.R. Surface morphology and compound layer pores of plasma nitrocarburized low carbon steel. Metall Mater Trans A 27, 135–143 (1996). https://doi.org/10.1007/BF02647754

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02647754