Abstract

Thermodynamics have long been applied to our understanding of the reactive wetting phenomena in metal-ceramic joining. We postulate the existence of a “solvent effect” due to the interaction between the reactive element addition and the brazing alloy. This effect plays a significant role in reactive wetting. By taking this effect into account, more realistic reactivities of different reactive element additions into a given brazing base alloy are predicted. Irreversible thermodynamics are also used to characterize the driving forces for reactive metal-ceramic joining.

Similar content being viewed by others

Abbreviations

- α:

-

equilibrium progressive factor

- γ:

-

activity coefficient

- Г:

-

surface excess

- ν, ξ:

-

chemical stoichiometries of compound

- Ξ:

-

=[ΔG o(ReXν - ΔH M(Re)/gn]

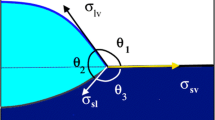

- σ:

-

surface tension

- μ:

-

chemical potential

- Π:

-

surface area

- ρ:

-

density

- Θ:

-

contact angle

- ω:

-

= (L 1w -L wgl Г i )R

- a :

-

activity

- G :

-

Gibbs energy

- R:

-

gas constant

- T :

-

temperature

- H M :

-

partial mole enthalphy of mixing

- x :

-

mole fraction

- S, s :

-

entropy, entropy per unit mass

- U, u :

-

internal energy, internal energy per unit mass

- p :

-

pressure

- V :

-

volume

- N, n :

-

moles of component, moles of component per unit mass

- v :

-

velocity

- t :

-

time

- J :

-

flux

- K :

-

rate of chemical reaction

- F :

-

body force

- g :

-

acceleration due to gravity

- A :

-

chemical affinity

- e :

-

surface area per unit mass

- L :

-

phenomenological coefficient

References

I.A. Aksay, C.E. Hoge, and J.A. Pask:J. Phys. Chem., 1974, vol. 78, p. 1178.

J.E. McDonald and J.G. Eberhart:TMS-AIME, 1965, vol. 233, p. 512.

D. Chatain, I. Rivollet, and N. Eustathopoulos:J. Chim. Phys., 1986, vol. 83, p. 561.

F.G. Yost and A.D. Romig, Jr.:Mater. Res. Soc. Symp. Proc, 1988, vol. 108, p. 385.

P.R. Chidambaram, G.R. Edwards, and D.L. Olson:Metall. Trans. B, 1992, vol. 23B, pp. 215–22.

E.T. Turkdogan:Physical Chemistry of High Temperature Technology, Academic Press, New York, NY, 1980, p. 93.

R.R. Kapoor and T.W. Eagar:Metall. Trans. B, 1989, vol. 20B, pp. 919–24.

R.R. Kapoor and T.W. Eagar:Ceramic Engineering and Science Proceedings, American Ceramic Society, Westerville, OH, 1989, p. 1613.

M. Naka and I. Okamoto:Trans. JWRI, 1985, vol. 14, pp. 29–34.

A.R. Miedema, F.R. de Boer, and R. Boom:CALPHAD, 1977, vol. 1, p. 341.

C. Wagner:Thermodynamics of Alloys, Addison-Wesley Press Inc., Cambridge, MA, 1952, p. 25.

L.B. Pankrantz, J.M. Stuve, and N.A. Gokcen:Thermodynamic Data for Mineral Technology, U.S. Bureau of Mines Bull. 677, U.S. Government Printing Office, Washington, DC, 1984.

J.J. Pak, M.L. Santella, and R.J. Fruehan:Metall. Trans. B, 1990, vol. 21B, pp. 349–55.

P. Glasdorff and I. Prigogine:Physica, 1964, vol. 30, p. 351.

R.B. Bird, W.E. Steward, and E.N. Lightfoot:Transport Phenomena, John Wiley & Sons, Inc., New York, NY, 1960.

S.R. de Groot and P. Mazur:Non-Equilibrium Thermodynamics, North Holland Publishing Co., Amsterdam, 1962.

T. Young:Phil. Trans. R. Soc. London, 1805, vol. 95, p. 65.

F. Brochard-Wyart and P.G. de Gennes:Adv. Colloid Interface Sci., 1992, vol. 39, p. 1.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Wang, G., Lannutti, J.J. Chemical thermodynamics as a predictive tool in the reactive metal brazing of ceramics. Metall Mater Trans A 26, 1499–1505 (1995). https://doi.org/10.1007/BF02647601

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02647601