Abstract

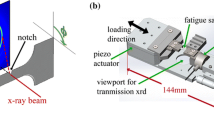

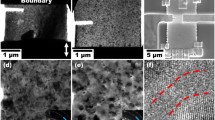

The initiation and propagation of nanometer-scale cracks have been investigated in detail byin situ transmission electron microscope (TEM) observations for the intermetallic compound Fe3Al under mode I loading. No dislocation was detected and no dislocation emission was found when cracks propagated directly from the thin edge of a double-jet hole where the thickness of the foil was below a critical thinness. Thinning took place in the thicker region of the foils because a great number of dislocations were emitted from the crack tip, and then an electron semitransparent region was formed in front of the crack tip. Following this process, a dislocation-free zone (DFZ) was formed. The maximum normal stress occurs in the zone. Nanometer-scale cracks initiated discontinuously ahead of the main crack tip in the highly stressed zone. The size of the smallest nanocrack observed was about 3 nm, and the tip radius of the nanocracks was less than 1 nm when the applied loading was low. The radius of the main crack tip was about 2.5 nm. The distances between discontinuous nanocracks and the main crack tip were about 5 to 60 nm, depending on the applied tensile loading. A relationship was found between the tensile loading and the nanocrack distance from the crack tip. The distance increases with the tensile loading, which is consistent with an “elastic-plastic” theoretical model.

Similar content being viewed by others

References

A.H. Cottrell:Trans. AIME, 1958, vol. 212, p. 192.

A.N. Stroh:Proc. R. Soc. London A, 1955, vol. 232, p. 548.

M.H. Kamdar:Metall. Trans. A, 1971, vol. 2, pp. 485–89.

M.J. Lii, X.F. Chen, Y. Katz, and W.W. Gerberich:Acta Metall., 1990, vol. 38, p. 2435.

H. Huang and W.W. Gerberich:Acta Metall., 1992, vol. 40, p. 2873.

J.R. Rice and R. Thomson:Phil. Mag., 1974, vol. 29, p. 73.

J. Weertman, L.-H. Lin, and R. Thomson:Acta Metall., 1983, vol. 31, p. 473.

S.H. Dai and J.C.M. Li:Scripta Metall., 1982, vol. 16, p. 183.

R. Thomson:Scripta Metall., 1986, vol. 20, p. 1473.

J.C.M. Li:Scripta Metall., 1986, vol. 20, p. 1477.

I.H. Lin and R. Thomson:Acta Metall., 1986, vol. 34, p. 187.

W.L. Li and J.C.M. Li:Phil. Mag. A, 1989, vol. 59, p. 1245.

X. Chen, T. Feocke, M. Lii, Y. Katz, and W.W. Gerberich:Eng. Fract. Mech., 1990, vol. 35, p. 987.

W. Zielinski, M.J. Lii, and W.W. Gerberich:Acta Metall., 1992, vol. 40, p. 2861.

P.G. Marsh, W. Zielinski, H. Huang, and W.W. Gerberich:Acta Metall., 1992, vol. 40, p. 2883.

S.H. Chen, Y. Katz, and W.W. Gerberich:Phil. Mag. A, 1991, vol. 63, p. 131.

Q.Z. Chen, W.Y. Chu, and J.M. Xiao:Sci. China A, in press.

Y. Zhang, W.Y. Chu, and J.M. Xiao:Sci. China, in press.

K.W. Gao, W.Y. Chu, and J.M. Xiao:Scripta Metall., in press.

C.T. Liu and K.S. Kumar:J. Min. Met. Mater. Soc., 1993, vol. 45(5), p. 38.

C.G. McKamey, J.H. DeVan, P.F. Tortorell, and V.K. Sikka:J. Mater. Res., 1991, vol. 6, p. 1779.

J.A. Horton, C.T. Liu, and C.C. Koch: inHigh-Temperature Alloys: Theory and Design, J.O. Stiegler, ed., TMS, Warrendale, PA, 1984, p. 309.

M.H. Yoo and C.L. Fu:Mater. Sci. Eng. A, 1992, vol. 153, p. 470.

H. Inouye: inHigh-Temperature Intermetallic Alloys, Materials Research Society Proceedings, C.C. Koch, C.T. Liu, and N.S. Stoloff, eds., Materials Research Society, Pittsburgh, PA, 1985, vol. 39, p. 255.

L.J. Qiao, X. Mao, and C.Z. Chen: unpublished research, 1994.

S.M. Ohr:Mater. Sci. Eng., 1985, vol. 72, p. 1.

H.G.F. Wilsdorf:Mater. Sci. Eng., 1983, vol. 59, p. 1.

H.G.F. Wilsdorf:Acta Metall., 1982, vol. 30, p. 1247.

W.W. Gerberich and T.J. Foecke:Hydrogen Effects on Material Behavior, R. Moody and A.W. Thompson, eds., TMS, Warrendale, PA, 1989, p. 687.

C.R. Barrett, W.D. Nix, and A.S. Tetelman:The Principles of Engineering Materials, Prentice-Hall Inc., Englewood Cliffs, NJ, 1973, p. 243.

L.P. Pook and R.A. Smith: inFracture Mechanics, Proceedings of a Conference at Cambridge University, R.A. Smith, ed., 1979, p. 64.

J.A. Horton and S.M. Ohr:J. Mater. Sci., 1982, vol. 17, p. 3140.

J.A. Horton: Oak Ridge National Laboratory, Oak Ridge, TN, private communication, 1994.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Qiao, L.J., Mao, X. & Chen, C.Z. Nanometer-scale crack initiation and propagation behavior of Fe3Al-based intermetallic alloy. Metall Mater Trans A 26, 1461–1469 (1995). https://doi.org/10.1007/BF02647597

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02647597